PDF Publication Title:

Text from PDF Page: 079

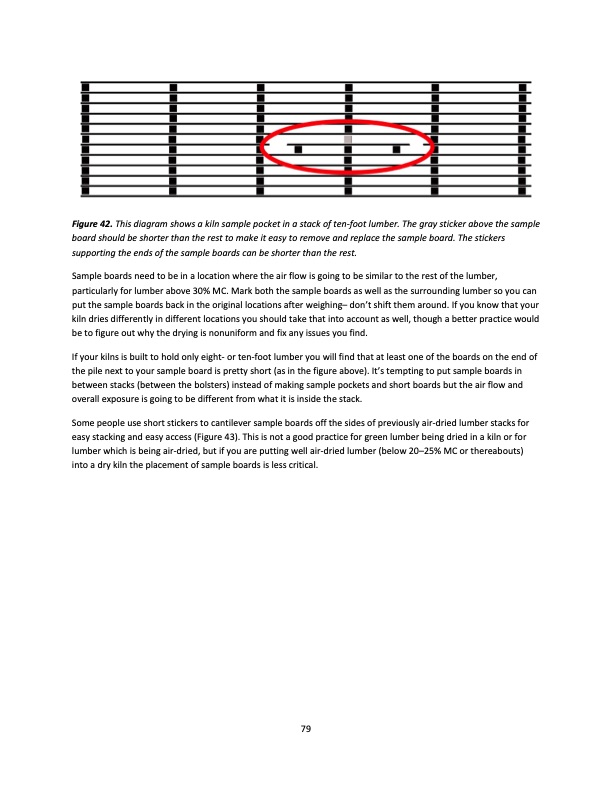

Figure 42. This diagram shows a kiln sample pocket in a stack of ten-foot lumber. The gray sticker above the sample board should be shorter than the rest to make it easy to remove and replace the sample board. The stickers supporting the ends of the sample boards can be shorter than the rest. Sample boards need to be in a location where the air flow is going to be similar to the rest of the lumber, particularly for lumber above 30% MC. Mark both the sample boards as well as the surrounding lumber so you can put the sample boards back in the original locations after weighing– don’t shift them around. If you know that your kiln dries differently in different locations you should take that into account as well, though a better practice would be to figure out why the drying is nonuniform and fix any issues you find. If your kilns is built to hold only eight- or ten-foot lumber you will find that at least one of the boards on the end of the pile next to your sample board is pretty short (as in the figure above). It’s tempting to put sample boards in between stacks (between the bolsters) instead of making sample pockets and short boards but the air flow and overall exposure is going to be different from what it is inside the stack. Some people use short stickers to cantilever sample boards off the sides of previously air-dried lumber stacks for easy stacking and easy access (Figure 43). This is not a good practice for green lumber being dried in a kiln or for lumber which is being air-dried, but if you are putting well air-dried lumber (below 20–25% MC or thereabouts) into a dry kiln the placement of sample boards is less critical. 79PDF Image | HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNS

PDF Search Title:

HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNSOriginal File Name Searched:

FOR128.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |