PDF Publication Title:

Text from PDF Page: 068

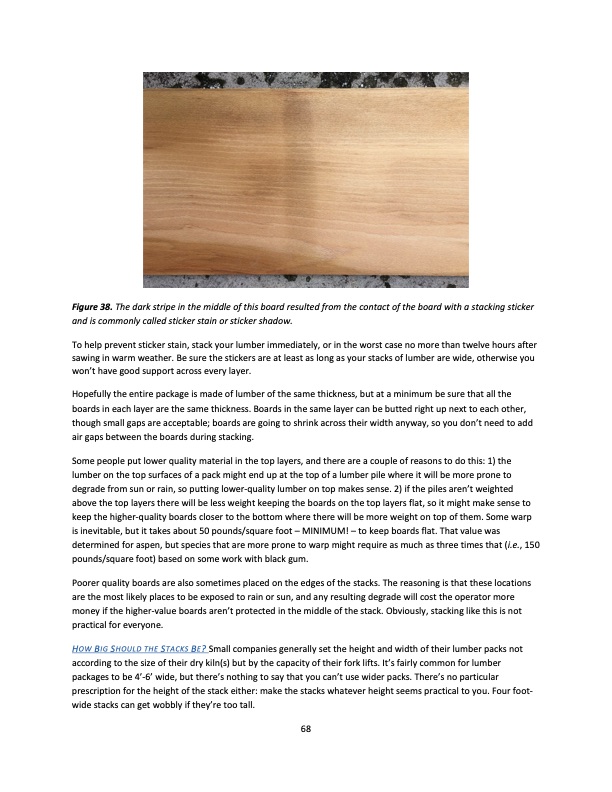

Figure 38. The dark stripe in the middle of this board resulted from the contact of the board with a stacking sticker and is commonly called sticker stain or sticker shadow. To help prevent sticker stain, stack your lumber immediately, or in the worst case no more than twelve hours after sawing in warm weather. Be sure the stickers are at least as long as your stacks of lumber are wide, otherwise you won’t have good support across every layer. Hopefully the entire package is made of lumber of the same thickness, but at a minimum be sure that all the boards in each layer are the same thickness. Boards in the same layer can be butted right up next to each other, though small gaps are acceptable; boards are going to shrink across their width anyway, so you don’t need to add air gaps between the boards during stacking. Some people put lower quality material in the top layers, and there are a couple of reasons to do this: 1) the lumber on the top surfaces of a pack might end up at the top of a lumber pile where it will be more prone to degrade from sun or rain, so putting lower-quality lumber on top makes sense. 2) if the piles aren’t weighted above the top layers there will be less weight keeping the boards on the top layers flat, so it might make sense to keep the higher-quality boards closer to the bottom where there will be more weight on top of them. Some warp is inevitable, but it takes about 50 pounds/square foot – MINIMUM! – to keep boards flat. That value was determined for aspen, but species that are more prone to warp might require as much as three times that (i.e., 150 pounds/square foot) based on some work with black gum. Poorer quality boards are also sometimes placed on the edges of the stacks. The reasoning is that these locations are the most likely places to be exposed to rain or sun, and any resulting degrade will cost the operator more money if the higher-value boards aren’t protected in the middle of the stack. Obviously, stacking like this is not practical for everyone. HOW BIG SHOULD THE STACKS BE? Small companies generally set the height and width of their lumber packs not according to the size of their dry kiln(s) but by the capacity of their fork lifts. It’s fairly common for lumber packages to be 4’-6’ wide, but there’s nothing to say that you can’t use wider packs. There’s no particular prescription for the height of the stack either: make the stacks whatever height seems practical to you. Four foot- wide stacks can get wobbly if they’re too tall. 68PDF Image | HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNS

PDF Search Title:

HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNSOriginal File Name Searched:

FOR128.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |