PDF Publication Title:

Text from PDF Page: 060

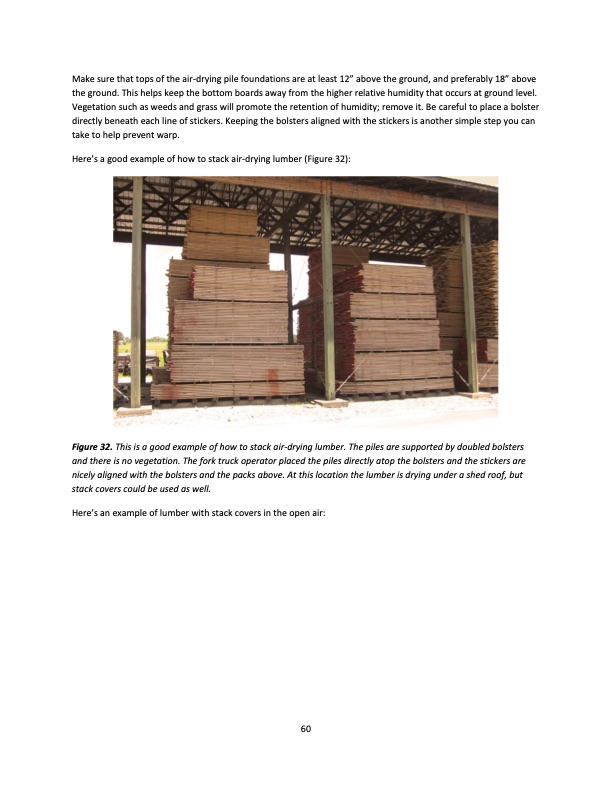

Make sure that tops of the air-drying pile foundations are at least 12” above the ground, and preferably 18” above the ground. This helps keep the bottom boards away from the higher relative humidity that occurs at ground level. Vegetation such as weeds and grass will promote the retention of humidity; remove it. Be careful to place a bolster directly beneath each line of stickers. Keeping the bolsters aligned with the stickers is another simple step you can take to help prevent warp. Here’s a good example of how to stack air-drying lumber (Figure 32): Figure 32. This is a good example of how to stack air-drying lumber. The piles are supported by doubled bolsters and there is no vegetation. The fork truck operator placed the piles directly atop the bolsters and the stickers are nicely aligned with the bolsters and the packs above. At this location the lumber is drying under a shed roof, but stack covers could be used as well. Here’s an example of lumber with stack covers in the open air: 60PDF Image | HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNS

PDF Search Title:

HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNSOriginal File Name Searched:

FOR128.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |