PDF Publication Title:

Text from PDF Page: 058

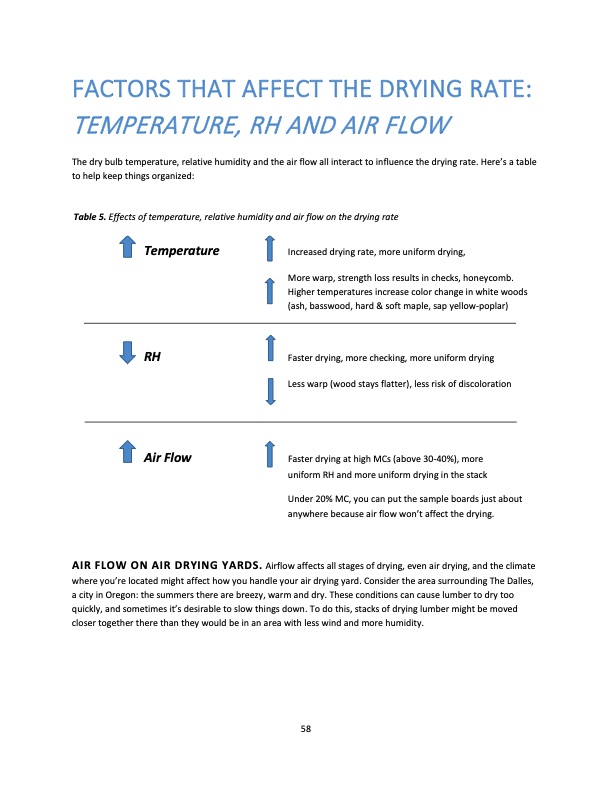

FACTORS THAT AFFECT THE DRYING RATE: TEMPERATURE, RH AND AIR FLOW The dry bulb temperature, relative humidity and the air flow all interact to influence the drying rate. Here’s a table to help keep things organized: Table 5. Effects of temperature, relative humidity and air flow on the drying rate Temperature RH Air Flow Increased drying rate, more uniform drying, More warp, strength loss results in checks, honeycomb. Higher temperatures increase color change in white woods (ash, basswood, hard & soft maple, sap yellow-poplar) Faster drying, more checking, more uniform drying Less warp (wood stays flatter), less risk of discoloration Faster drying at high MCs (above 30-40%), more uniform RH and more uniform drying in the stack Under 20% MC, you can put the sample boards just about anywhere because air flow won’t affect the drying. AIR FLOW ON AIR DRYING YARDS. Airflow affects all stages of drying, even air drying, and the climate where you’re located might affect how you handle your air drying yard. Consider the area surrounding The Dalles, a city in Oregon: the summers there are breezy, warm and dry. These conditions can cause lumber to dry too quickly, and sometimes it’s desirable to slow things down. To do this, stacks of drying lumber might be moved closer together there than they would be in an area with less wind and more humidity. 58PDF Image | HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNS

PDF Search Title:

HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNSOriginal File Name Searched:

FOR128.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |