PDF Publication Title:

Text from PDF Page: 056

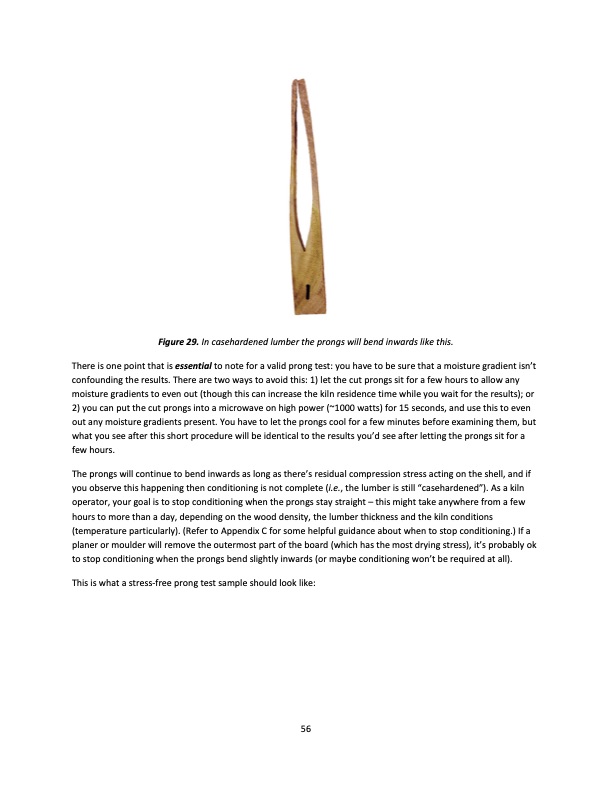

Figure 29. In casehardened lumber the prongs will bend inwards like this. There is one point that is essential to note for a valid prong test: you have to be sure that a moisture gradient isn’t confounding the results. There are two ways to avoid this: 1) let the cut prongs sit for a few hours to allow any moisture gradients to even out (though this can increase the kiln residence time while you wait for the results); or 2) you can put the cut prongs into a microwave on high power (~1000 watts) for 15 seconds, and use this to even out any moisture gradients present. You have to let the prongs cool for a few minutes before examining them, but what you see after this short procedure will be identical to the results you’d see after letting the prongs sit for a few hours. The prongs will continue to bend inwards as long as there’s residual compression stress acting on the shell, and if you observe this happening then conditioning is not complete (i.e., the lumber is still “casehardened”). As a kiln operator, your goal is to stop conditioning when the prongs stay straight – this might take anywhere from a few hours to more than a day, depending on the wood density, the lumber thickness and the kiln conditions (temperature particularly). (Refer to Appendix C for some helpful guidance about when to stop conditioning.) If a planer or moulder will remove the outermost part of the board (which has the most drying stress), it’s probably ok to stop conditioning when the prongs bend slightly inwards (or maybe conditioning won’t be required at all). This is what a stress-free prong test sample should look like: 56PDF Image | HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNS

PDF Search Title:

HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNSOriginal File Name Searched:

FOR128.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |