PDF Publication Title:

Text from PDF Page: 050

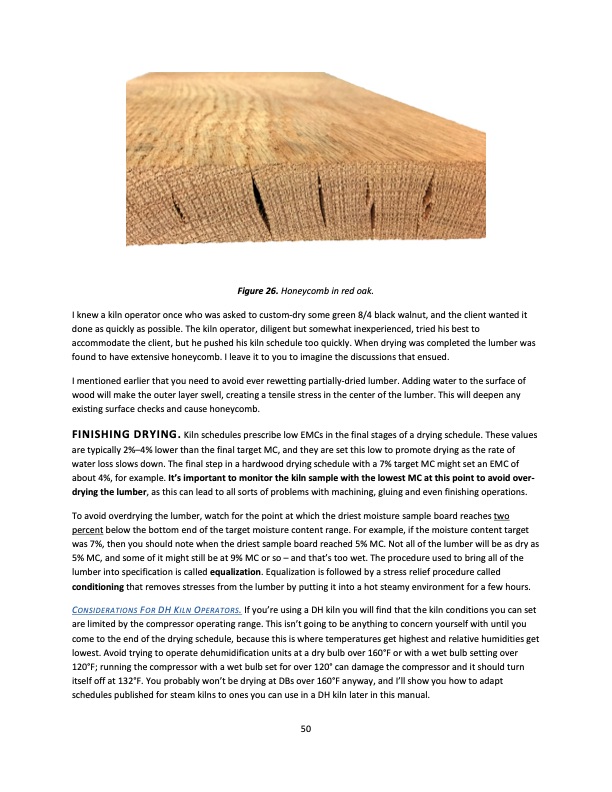

Figure 26. Honeycomb in red oak. I knew a kiln operator once who was asked to custom-dry some green 8/4 black walnut, and the client wanted it done as quickly as possible. The kiln operator, diligent but somewhat inexperienced, tried his best to accommodate the client, but he pushed his kiln schedule too quickly. When drying was completed the lumber was found to have extensive honeycomb. I leave it to you to imagine the discussions that ensued. I mentioned earlier that you need to avoid ever rewetting partially-dried lumber. Adding water to the surface of wood will make the outer layer swell, creating a tensile stress in the center of the lumber. This will deepen any existing surface checks and cause honeycomb. FINISHING DRYING. Kiln schedules prescribe low EMCs in the final stages of a drying schedule. These values are typically 2%–4% lower than the final target MC, and they are set this low to promote drying as the rate of water loss slows down. The final step in a hardwood drying schedule with a 7% target MC might set an EMC of about 4%, for example. It’s important to monitor the kiln sample with the lowest MC at this point to avoid over- drying the lumber, as this can lead to all sorts of problems with machining, gluing and even finishing operations. To avoid overdrying the lumber, watch for the point at which the driest moisture sample board reaches two percent below the bottom end of the target moisture content range. For example, if the moisture content target was 7%, then you should note when the driest sample board reached 5% MC. Not all of the lumber will be as dry as 5% MC, and some of it might still be at 9% MC or so – and that’s too wet. The procedure used to bring all of the lumber into specification is called equalization. Equalization is followed by a stress relief procedure called conditioning that removes stresses from the lumber by putting it into a hot steamy environment for a few hours. CONSIDERATIONS FOR DH KILN OPERATORS. If you’re using a DH kiln you will find that the kiln conditions you can set are limited by the compressor operating range. This isn’t going to be anything to concern yourself with until you come to the end of the drying schedule, because this is where temperatures get highest and relative humidities get lowest. Avoid trying to operate dehumidification units at a dry bulb over 160°F or with a wet bulb setting over 120°F; running the compressor with a wet bulb set for over 120° can damage the compressor and it should turn itself off at 132°F. You probably won’t be drying at DBs over 160°F anyway, and I’ll show you how to adapt schedules published for steam kilns to ones you can use in a DH kiln later in this manual. 50PDF Image | HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNS

PDF Search Title:

HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNSOriginal File Name Searched:

FOR128.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |