PDF Publication Title:

Text from PDF Page: 048

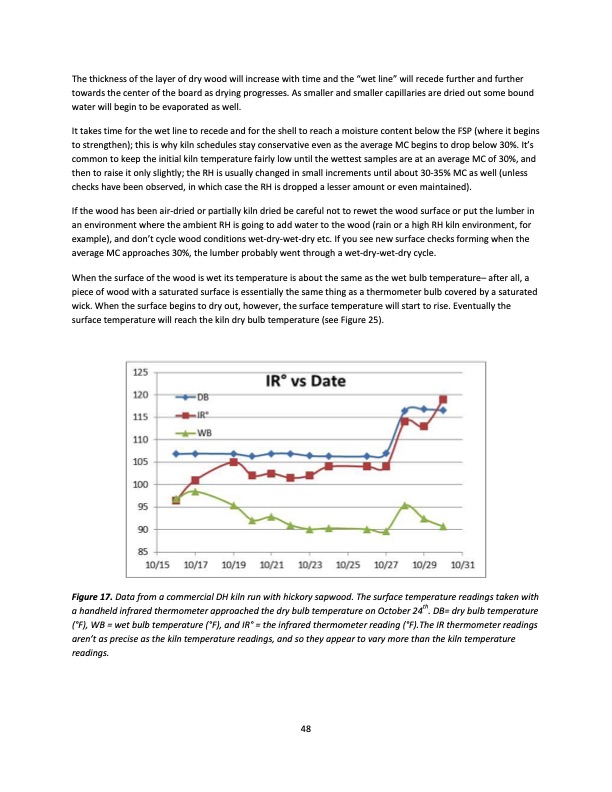

The thickness of the layer of dry wood will increase with time and the “wet line” will recede further and further towards the center of the board as drying progresses. As smaller and smaller capillaries are dried out some bound water will begin to be evaporated as well. It takes time for the wet line to recede and for the shell to reach a moisture content below the FSP (where it begins to strengthen); this is why kiln schedules stay conservative even as the average MC begins to drop below 30%. It’s common to keep the initial kiln temperature fairly low until the wettest samples are at an average MC of 30%, and then to raise it only slightly; the RH is usually changed in small increments until about 30-35% MC as well (unless checks have been observed, in which case the RH is dropped a lesser amount or even maintained). If the wood has been air-dried or partially kiln dried be careful not to rewet the wood surface or put the lumber in an environment where the ambient RH is going to add water to the wood (rain or a high RH kiln environment, for example), and don’t cycle wood conditions wet-dry-wet-dry etc. If you see new surface checks forming when the average MC approaches 30%, the lumber probably went through a wet-dry-wet-dry cycle. When the surface of the wood is wet its temperature is about the same as the wet bulb temperature– after all, a piece of wood with a saturated surface is essentially the same thing as a thermometer bulb covered by a saturated wick. When the surface begins to dry out, however, the surface temperature will start to rise. Eventually the surface temperature will reach the kiln dry bulb temperature (see Figure 25). Figure 17. Data from a commercial DH kiln run with hickory sapwood. The surface temperature readings taken with a handheld infrared thermometer approached the dry bulb temperature on October 24th. DB= dry bulb temperature (°F), WB = wet bulb temperature (°F), and IR° = the infrared thermometer reading (°F).The IR thermometer readings aren’t as precise as the kiln temperature readings, and so they appear to vary more than the kiln temperature readings. 48PDF Image | HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNS

PDF Search Title:

HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNSOriginal File Name Searched:

FOR128.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |