PDF Publication Title:

Text from PDF Page: 044

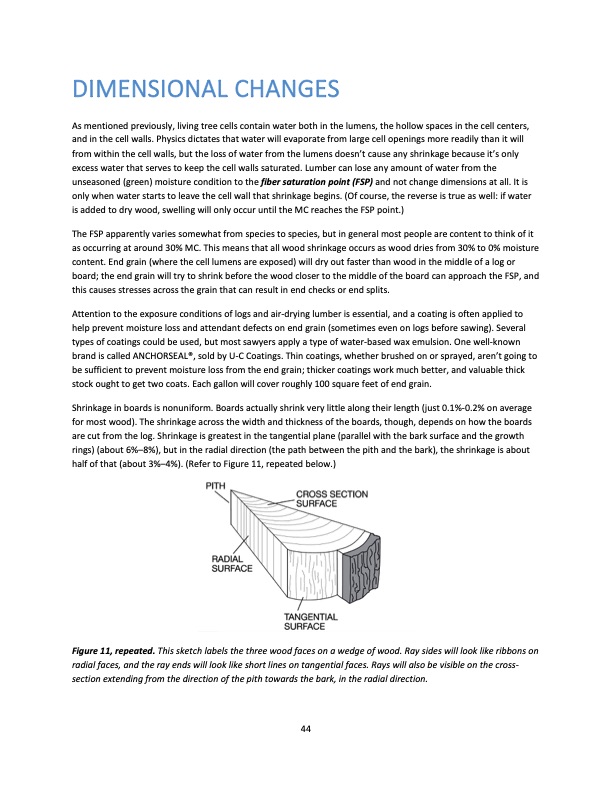

DIMENSIONAL CHANGES As mentioned previously, living tree cells contain water both in the lumens, the hollow spaces in the cell centers, and in the cell walls. Physics dictates that water will evaporate from large cell openings more readily than it will from within the cell walls, but the loss of water from the lumens doesn’t cause any shrinkage because it’s only excess water that serves to keep the cell walls saturated. Lumber can lose any amount of water from the unseasoned (green) moisture condition to the fiber saturation point (FSP) and not change dimensions at all. It is only when water starts to leave the cell wall that shrinkage begins. (Of course, the reverse is true as well: if water is added to dry wood, swelling will only occur until the MC reaches the FSP point.) The FSP apparently varies somewhat from species to species, but in general most people are content to think of it as occurring at around 30% MC. This means that all wood shrinkage occurs as wood dries from 30% to 0% moisture content. End grain (where the cell lumens are exposed) will dry out faster than wood in the middle of a log or board; the end grain will try to shrink before the wood closer to the middle of the board can approach the FSP, and this causes stresses across the grain that can result in end checks or end splits. Attention to the exposure conditions of logs and air-drying lumber is essential, and a coating is often applied to help prevent moisture loss and attendant defects on end grain (sometimes even on logs before sawing). Several types of coatings could be used, but most sawyers apply a type of water-based wax emulsion. One well-known brand is called ANCHORSEAL®, sold by U-C Coatings. Thin coatings, whether brushed on or sprayed, aren’t going to be sufficient to prevent moisture loss from the end grain; thicker coatings work much better, and valuable thick stock ought to get two coats. Each gallon will cover roughly 100 square feet of end grain. Shrinkage in boards is nonuniform. Boards actually shrink very little along their length (just 0.1%-0.2% on average for most wood). The shrinkage across the width and thickness of the boards, though, depends on how the boards are cut from the log. Shrinkage is greatest in the tangential plane (parallel with the bark surface and the growth rings) (about 6%–8%), but in the radial direction (the path between the pith and the bark), the shrinkage is about half of that (about 3%–4%). (Refer to Figure 11, repeated below.) Figure 11, repeated. This sketch labels the three wood faces on a wedge of wood. Ray sides will look like ribbons on radial faces, and the ray ends will look like short lines on tangential faces. Rays will also be visible on the cross- section extending from the direction of the pith towards the bark, in the radial direction. 44PDF Image | HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNS

PDF Search Title:

HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNSOriginal File Name Searched:

FOR128.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |