PDF Publication Title:

Text from PDF Page: 042

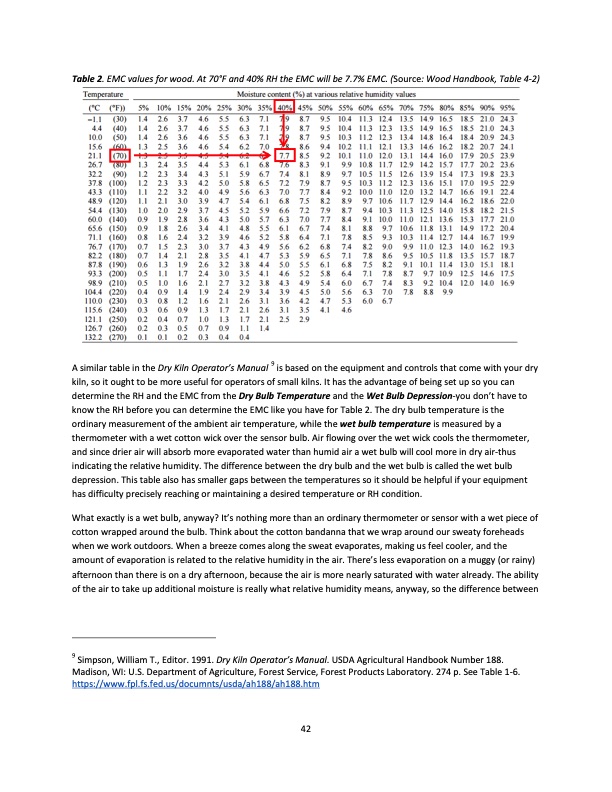

Table 2. EMC values for wood. At 70°F and 40% RH the EMC will be 7.7% EMC. (Source: Wood Handbook, Table 4-2) A similar table in the Dry Kiln Operator’s Manual 9 is based on the equipment and controls that come with your dry kiln, so it ought to be more useful for operators of small kilns. It has the advantage of being set up so you can determine the RH and the EMC from the Dry Bulb Temperature and the Wet Bulb Depression-you don’t have to know the RH before you can determine the EMC like you have for Table 2. The dry bulb temperature is the ordinary measurement of the ambient air temperature, while the wet bulb temperature is measured by a thermometer with a wet cotton wick over the sensor bulb. Air flowing over the wet wick cools the thermometer, and since drier air will absorb more evaporated water than humid air a wet bulb will cool more in dry air-thus indicating the relative humidity. The difference between the dry bulb and the wet bulb is called the wet bulb depression. This table also has smaller gaps between the temperatures so it should be helpful if your equipment has difficulty precisely reaching or maintaining a desired temperature or RH condition. What exactly is a wet bulb, anyway? It’s nothing more than an ordinary thermometer or sensor with a wet piece of cotton wrapped around the bulb. Think about the cotton bandanna that we wrap around our sweaty foreheads when we work outdoors. When a breeze comes along the sweat evaporates, making us feel cooler, and the amount of evaporation is related to the relative humidity in the air. There’s less evaporation on a muggy (or rainy) afternoon than there is on a dry afternoon, because the air is more nearly saturated with water already. The ability of the air to take up additional moisture is really what relative humidity means, anyway, so the difference between 9 Simpson, William T., Editor. 1991. Dry Kiln Operator’s Manual. USDA Agricultural Handbook Number 188. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. 274 p. See Table 1-6. https://www.fpl.fs.fed.us/documnts/usda/ah188/ah188.htm 42PDF Image | HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNS

PDF Search Title:

HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNSOriginal File Name Searched:

FOR128.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |