PDF Publication Title:

Text from PDF Page: 033

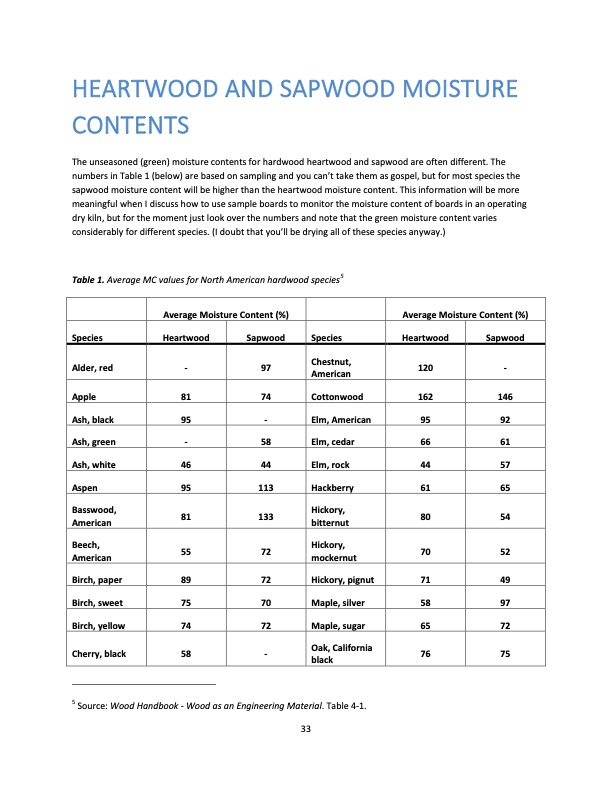

HEARTWOOD AND SAPWOOD MOISTURE CONTENTS The unseasoned (green) moisture contents for hardwood heartwood and sapwood are often different. The numbers in Table 1 (below) are based on sampling and you can’t take them as gospel, but for most species the sapwood moisture content will be higher than the heartwood moisture content. This information will be more meaningful when I discuss how to use sample boards to monitor the moisture content of boards in an operating dry kiln, but for the moment just look over the numbers and note that the green moisture content varies considerably for different species. (I doubt that you’ll be drying all of these species anyway.) Table 1. Average MC values for North American hardwood species5 Average Moisture Content (%) Species Alder, red Apple Ash, black Ash, green Ash, white Aspen Basswood, American Beech, American Birch, paper Birch, sweet Birch, yellow Cherry, black Heartwood Sapwood - 97 81 74 95 - - 58 46 44 95 113 81 133 55 72 89 72 75 70 74 72 58 - Average Moisture Content (%) Species Heartwood Sapwood Chestnut, 120 - American Cottonwood 162 146 Elm, American Elm, cedar Elm, rock Hackberry Hickory, bitternut Hickory, mockernut Hickory, pignut Maple, silver Maple, sugar Oak, California black 95 92 66 61 44 57 61 65 80 54 70 52 71 49 58 97 65 72 76 75 5 Source: Wood Handbook - Wood as an Engineering Material. Table 4-1. 33PDF Image | HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNS

PDF Search Title:

HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNSOriginal File Name Searched:

FOR128.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |