PDF Publication Title:

Text from PDF Page: 017

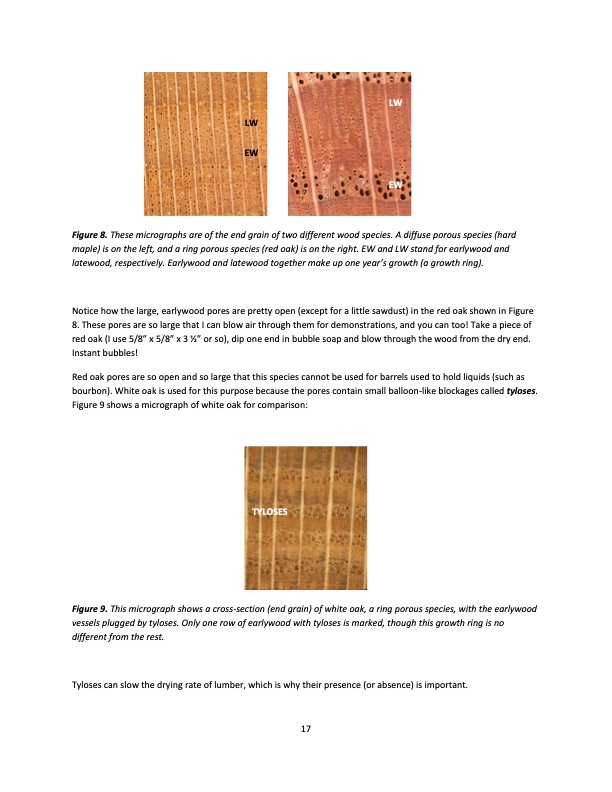

LW EW LW EW Figure 8. These micrographs are of the end grain of two different wood species. A diffuse porous species (hard maple) is on the left, and a ring porous species (red oak) is on the right. EW and LW stand for earlywood and latewood, respectively. Earlywood and latewood together make up one year’s growth (a growth ring). Notice how the large, earlywood pores are pretty open (except for a little sawdust) in the red oak shown in Figure 8. These pores are so large that I can blow air through them for demonstrations, and you can too! Take a piece of red oak (I use 5/8” x 5/8” x 3 1⁄2” or so), dip one end in bubble soap and blow through the wood from the dry end. Instant bubbles! Red oak pores are so open and so large that this species cannot be used for barrels used to hold liquids (such as bourbon). White oak is used for this purpose because the pores contain small balloon-like blockages called tyloses. Figure 9 shows a micrograph of white oak for comparison: TYLOSES Figure 9. This micrograph shows a cross-section (end grain) of white oak, a ring porous species, with the earlywood vessels plugged by tyloses. Only one row of earlywood with tyloses is marked, though this growth ring is no different from the rest. Tyloses can slow the drying rate of lumber, which is why their presence (or absence) is important. 17PDF Image | HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNS

PDF Search Title:

HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNSOriginal File Name Searched:

FOR128.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |