PDF Publication Title:

Text from PDF Page: 013

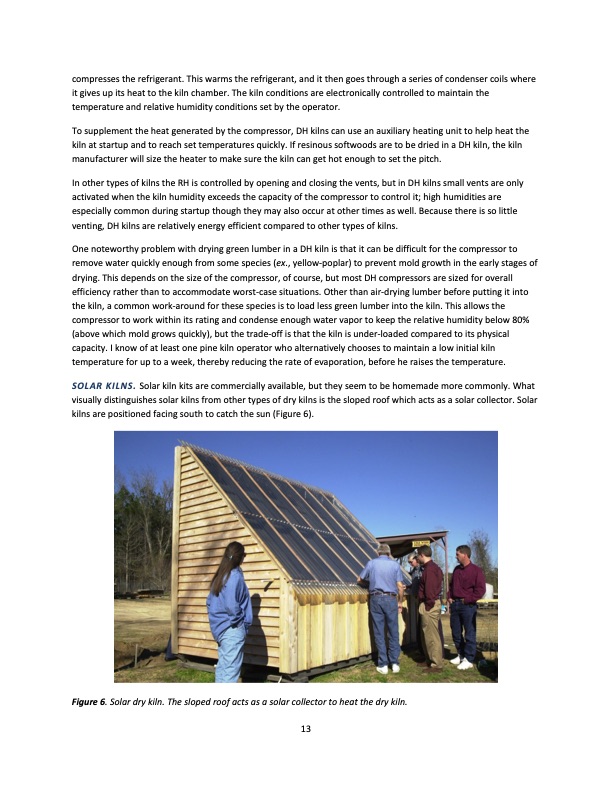

compresses the refrigerant. This warms the refrigerant, and it then goes through a series of condenser coils where it gives up its heat to the kiln chamber. The kiln conditions are electronically controlled to maintain the temperature and relative humidity conditions set by the operator. To supplement the heat generated by the compressor, DH kilns can use an auxiliary heating unit to help heat the kiln at startup and to reach set temperatures quickly. If resinous softwoods are to be dried in a DH kiln, the kiln manufacturer will size the heater to make sure the kiln can get hot enough to set the pitch. In other types of kilns the RH is controlled by opening and closing the vents, but in DH kilns small vents are only activated when the kiln humidity exceeds the capacity of the compressor to control it; high humidities are especially common during startup though they may also occur at other times as well. Because there is so little venting, DH kilns are relatively energy efficient compared to other types of kilns. One noteworthy problem with drying green lumber in a DH kiln is that it can be difficult for the compressor to remove water quickly enough from some species (ex., yellow-poplar) to prevent mold growth in the early stages of drying. This depends on the size of the compressor, of course, but most DH compressors are sized for overall efficiency rather than to accommodate worst-case situations. Other than air-drying lumber before putting it into the kiln, a common work-around for these species is to load less green lumber into the kiln. This allows the compressor to work within its rating and condense enough water vapor to keep the relative humidity below 80% (above which mold grows quickly), but the trade-off is that the kiln is under-loaded compared to its physical capacity. I know of at least one pine kiln operator who alternatively chooses to maintain a low initial kiln temperature for up to a week, thereby reducing the rate of evaporation, before he raises the temperature. SOLAR KILNS. Solar kiln kits are commercially available, but they seem to be homemade more commonly. What visually distinguishes solar kilns from other types of dry kilns is the sloped roof which acts as a solar collector. Solar kilns are positioned facing south to catch the sun (Figure 6). Figure 6. Solar dry kiln. The sloped roof acts as a solar collector to heat the dry kiln. 13PDF Image | HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNS

PDF Search Title:

HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNSOriginal File Name Searched:

FOR128.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |