PDF Publication Title:

Text from PDF Page: 057

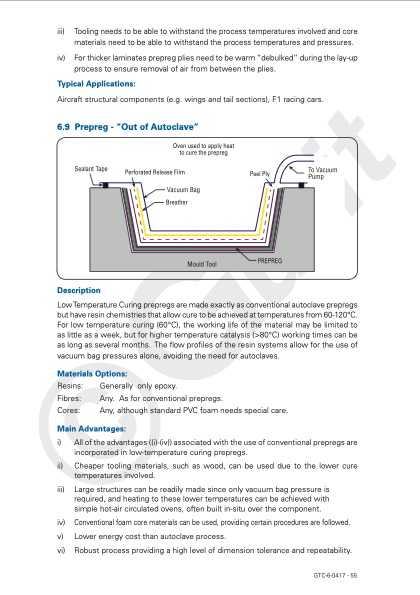

iii) Tooling needs to be able to withstand the process temperatures involved and core materials need to be able to withstand the process temperatures and pressures. iv) For thicker laminates prepreg plies need to be warm “debulked” during the lay-up process to ensure removal of air from between the plies. Typical Applications: Aircraft structural components (e.g. wings and tail sections), F1 racing cars. 6.9 Prepreg - “Out of Autoclave” Description LowTemperature Curing prepregs are made exactly as conventional autoclave prepregs but have resin chemistries that allow cure to be achieved at temperatures from 60-120°C. For low temperature curing (60°C), the working life of the material may be limited to as little as a week, but for higher temperature catalysis (>80°C) working times can be as long as several months. The flow profiles of the resin systems allow for the use of vacuum bag pressures alone, avoiding the need for autoclaves. Materials Options: Resins: Fibres: Cores: Generally only epoxy. Any. As for conventional prepregs. Any, although standard PVC foam needs special care. Main Advantages: i) All of the advantages ((i)-(iv)) associated with the use of conventional prepregs are incorporated in low-temperature curing prepregs. ii) Cheaper tooling materials, such as wood, can be used due to the lower cure temperatures involved. iii) Large structures can be readily made since only vacuum bag pressure is required, and heating to these lower temperatures can be achieved with simple hot-air circulated ovens, often built in-situ over the component. iv) Conventional foam core materials can be used, providing certain procedures are followed. v) Lower energy cost than autoclave process. vi) Robust process providing a high level of dimension tolerance and repeatability. GTC-6-0417 - 55PDF Image | GUIDE TO COMPOSITES

PDF Search Title:

GUIDE TO COMPOSITESOriginal File Name Searched:

guide-to-composites.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |