PDF Publication Title:

Text from PDF Page: 052

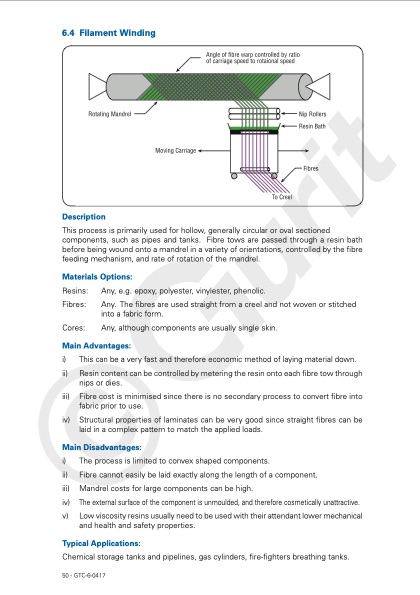

6.4 Filament Winding Description This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Fibre tows are passed through a resin bath before being wound onto a mandrel in a variety of orientations, controlled by the fibre feeding mechanism, and rate of rotation of the mandrel. Materials Options: Resins: Fibres: Cores: Any, e.g. epoxy, polyester, vinylester, phenolic. Any. The fibres are used straight from a creel and not woven or stitched into a fabric form. Any, although components are usually single skin. Main Advantages: i) This can be a very fast and therefore economic method of laying material down. ii) Resin content can be controlled by metering the resin onto each fibre tow through nips or dies. iii) Fibre cost is minimised since there is no secondary process to convert fibre into fabric prior to use. iv) Structural properties of laminates can be very good since straight fibres can be laid in a complex pattern to match the applied loads. Main Disadvantages: i) The process is limited to convex shaped components. ii) Fibre cannot easily be laid exactly along the length of a component. iii) Mandrel costs for large components can be high. iv) The external surface of the component is unmoulded, and therefore cosmetically unattractive. v) Low viscosity resins usually need to be used with their attendant lower mechanical and health and safety properties. Typical Applications: Chemical storage tanks and pipelines, gas cylinders, fire-fighters breathing tanks. 50 - GTC-6-0417PDF Image | GUIDE TO COMPOSITES

PDF Search Title:

GUIDE TO COMPOSITESOriginal File Name Searched:

guide-to-composites.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |