PDF Publication Title:

Text from PDF Page: 024

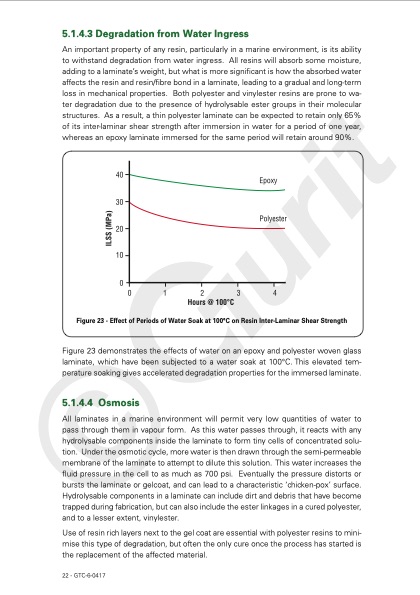

5.1.4.3 Degradation from Water Ingress An important property of any resin, particularly in a marine environment, is its ability to withstand degradation from water ingress. All resins will absorb some moisture, adding to a laminate’s weight, but what is more significant is how the absorbed water affects the resin and resin/fibre bond in a laminate, leading to a gradual and long-term loss in mechanical properties. Both polyester and vinylester resins are prone to wa- ter degradation due to the presence of hydrolysable ester groups in their molecular structures. As a result, a thin polyester laminate can be expected to retain only 65% of its inter-laminar shear strength after immersion in water for a period of one year, whereas an epoxy laminate immersed for the same period will retain around 90%. Figure 23 - Effect of Periods of Water Soak at 100°C on Resin Inter-Laminar Shear Strength Figure 23 demonstrates the effects of water on an epoxy and polyester woven glass laminate, which have been subjected to a water soak at 100°C. This elevated tem- perature soaking gives accelerated degradation properties for the immersed laminate. 5.1.4.4 Osmosis All laminates in a marine environment will permit very low quantities of water to pass through them in vapour form. As this water passes through, it reacts with any hydrolysable components inside the laminate to form tiny cells of concentrated solu- tion. Under the osmotic cycle, more water is then drawn through the semi-permeable membrane of the laminate to attempt to dilute this solution. This water increases the fluid pressure in the cell to as much as 700 psi. Eventually the pressure distorts or bursts the laminate or gelcoat, and can lead to a characteristic ‘chicken-pox’ surface. Hydrolysable components in a laminate can include dirt and debris that have become trapped during fabrication, but can also include the ester linkages in a cured polyester, and to a lesser extent, vinylester. Use of resin rich layers next to the gel coat are essential with polyester resins to mini- mise this type of degradation, but often the only cure once the process has started is the replacement of the affected material. 22 - GTC-6-0417PDF Image | GUIDE TO COMPOSITES

PDF Search Title:

GUIDE TO COMPOSITESOriginal File Name Searched:

guide-to-composites.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |