PDF Publication Title:

Text from PDF Page: 020

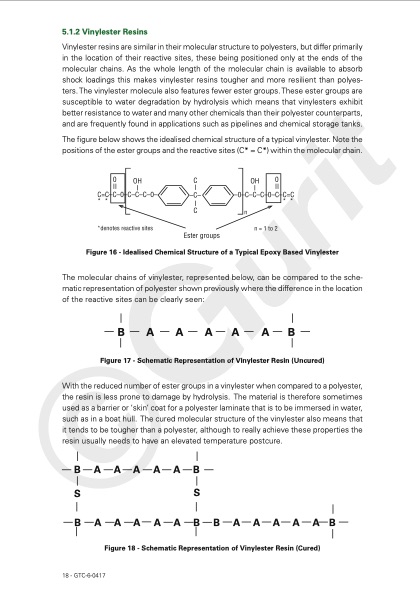

5.1.2 Vinylester Resins Vinylester resins are similar in their molecular structure to polyesters, but differ primarily in the location of their reactive sites, these being positioned only at the ends of the molecular chains. As the whole length of the molecular chain is available to absorb shock loadings this makes vinylester resins tougher and more resilient than polyes- ters. The vinylester molecule also features fewer ester groups. These ester groups are susceptible to water degradation by hydrolysis which means that vinylesters exhibit better resistance to water and many other chemicals than their polyester counterparts, and are frequently found in applications such as pipelines and chemical storage tanks. The figure below shows the idealised chemical structure of a typical vinylester. Note the positions of the ester groups and the reactive sites (C* = C*) within the molecular chain. Figure 16 - Idealised Chemical Structure of a Typical Epoxy Based Vinylester The molecular chains of vinylester, represented below, can be compared to the sche- matic representation of polyester shown previously where the difference in the location of the reactive sites can be clearly seen: BAAAAAB Figure 17 - Schematic Representation of Vinylester Resin (Uncured) With the reduced number of ester groups in a vinylester when compared to a polyester, the resin is less prone to damage by hydrolysis. The material is therefore sometimes used as a barrier or ‘skin’ coat for a polyester laminate that is to be immersed in water, such as in a boat hull. The cured molecular structure of the vinylester also means that it tends to be tougher than a polyester, although to really achieve these properties the resin usually needs to have an elevated temperature postcure. BAAAAAB SS BAAAAABBAAAAAB Figure 18 - Schematic Representation of Vinylester Resin (Cured) 18 - GTC-6-0417PDF Image | GUIDE TO COMPOSITES

PDF Search Title:

GUIDE TO COMPOSITESOriginal File Name Searched:

guide-to-composites.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |