PDF Publication Title:

Text from PDF Page: 118

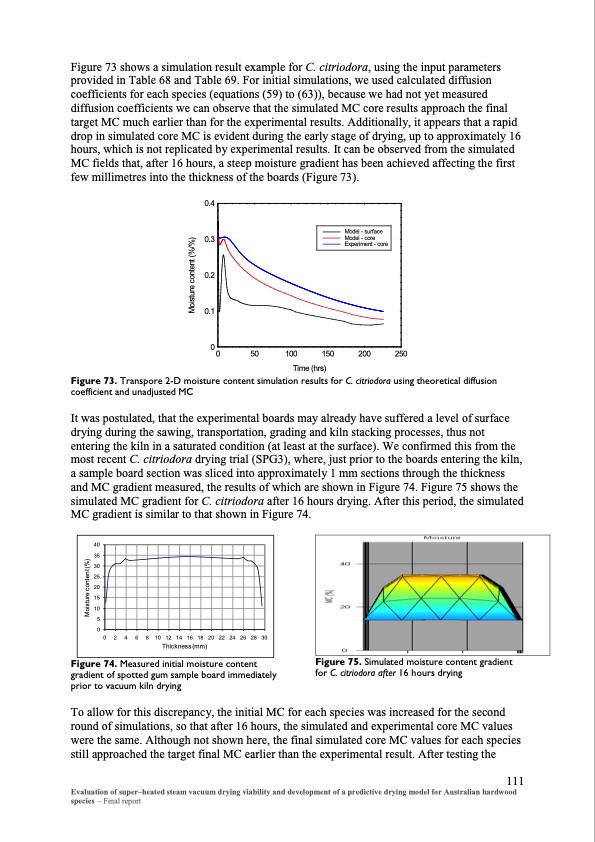

Figure 73 shows a simulation result example for C. citriodora, using the input parameters provided in Table 68 and Table 69. For initial simulations, we used calculated diffusion coefficients for each species (equations (59) to (63)), because we had not yet measured diffusion coefficients we can observe that the simulated MC core results approach the final target MC much earlier than for the experimental results. Additionally, it appears that a rapid drop in simulated core MC is evident during the early stage of drying, up to approximately 16 hours, which is not replicated by experimental results. It can be observed from the simulated MC fields that, after 16 hours, a steep moisture gradient has been achieved affecting the first few millimetres into the thickness of the boards (Figure 73). 0.4 0.3 0.2 0.1 0 0 50 100 150 200 250 Time (hrs) Model - surface Model - core Experiment - core Figure 73. Transpore 2-D moisture content simulation results for C. citriodora using theoretical diffusion coefficient and unadjusted MC It was postulated, that the experimental boards may already have suffered a level of surface drying during the sawing, transportation, grading and kiln stacking processes, thus not entering the kiln in a saturated condition (at least at the surface). We confirmed this from the most recent C. citriodora drying trial (SPG3), where, just prior to the boards entering the kiln, a sample board section was sliced into approximately 1 mm sections through the thickness and MC gradient measured, the results of which are shown in Figure 74. Figure 75 shows the simulated MC gradient for C. citriodora after 16 hours drying. After this period, the simulated MC gradient is similar to that shown in Figure 74. 40 35 30 25 20 15 10 5 0 0 2 4 6 8 1012141618202224262830 Thickness (mm) Figure 74. Measured initial moisture content gradient of spotted gum sample board immediately prior to vacuum kiln drying Figure 75. Simulated moisture content gradient for C. citriodora after 16 hours drying To allow for this discrepancy, the initial MC for each species was increased for the second round of simulations, so that after 16 hours, the simulated and experimental core MC values were the same. Although not shown here, the final simulated core MC values for each species still approached the target final MC earlier than the experimental result. After testing the 111 Evaluation of super–heated steam vacuum drying viability and development of a predictive drying model for Australian hardwood species – Final report Moisture content (%) Moisture content (%/%)PDF Image | Evaluation of super-heated steam vacuum drying

PDF Search Title:

Evaluation of super-heated steam vacuum dryingOriginal File Name Searched:

PN08_2047_Vacuum_Drying_Reviewed_Report.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |