PDF Publication Title:

Text from PDF Page: 115

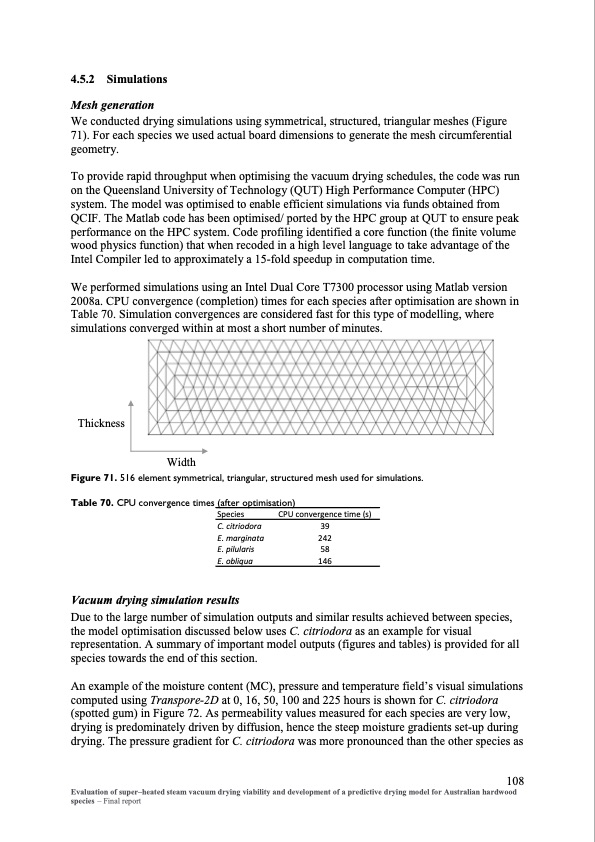

4.5.2 Simulations Mesh generation We conducted drying simulations using symmetrical, structured, triangular meshes (Figure 71). For each species we used actual board dimensions to generate the mesh circumferential geometry. To provide rapid throughput when optimising the vacuum drying schedules, the code was run on the Queensland University of Technology (QUT) High Performance Computer (HPC) system. The model was optimised to enable efficient simulations via funds obtained from QCIF. The Matlab code has been optimised/ ported by the HPC group at QUT to ensure peak performance on the HPC system. Code profiling identified a core function (the finite volume wood physics function) that when recoded in a high level language to take advantage of the Intel Compiler led to approximately a 15-fold speedup in computation time. We performed simulations using an Intel Dual Core T7300 processor using Matlab version 2008a. CPU convergence (completion) times for each species after optimisation are shown in Table 70. Simulation convergences are considered fast for this type of modelling, where simulations converged within at most a short number of minutes. Thickness Width Figure 71. 516 element symmetrical, triangular, structured mesh used for simulations. Table 70. CPU convergence times (after optimisation) Species C. citriodora E. marginata E. pilularis E. obliqua Vacuum drying simulation results CPU convergence time (s) 39 242 58 146 Due to the large number of simulation outputs and similar results achieved between species, the model optimisation discussed below uses C. citriodora as an example for visual representation. A summary of important model outputs (figures and tables) is provided for all species towards the end of this section. An example of the moisture content (MC), pressure and temperature field’s visual simulations computed using Transpore-2D at 0, 16, 50, 100 and 225 hours is shown for C. citriodora (spotted gum) in Figure 72. As permeability values measured for each species are very low, drying is predominately driven by diffusion, hence the steep moisture gradients set-up during drying. The pressure gradient for C. citriodora was more pronounced than the other species as 108 Evaluation of super–heated steam vacuum drying viability and development of a predictive drying model for Australian hardwood species – Final reportPDF Image | Evaluation of super-heated steam vacuum drying

PDF Search Title:

Evaluation of super-heated steam vacuum dryingOriginal File Name Searched:

PN08_2047_Vacuum_Drying_Reviewed_Report.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |