PDF Publication Title:

Text from PDF Page: 100

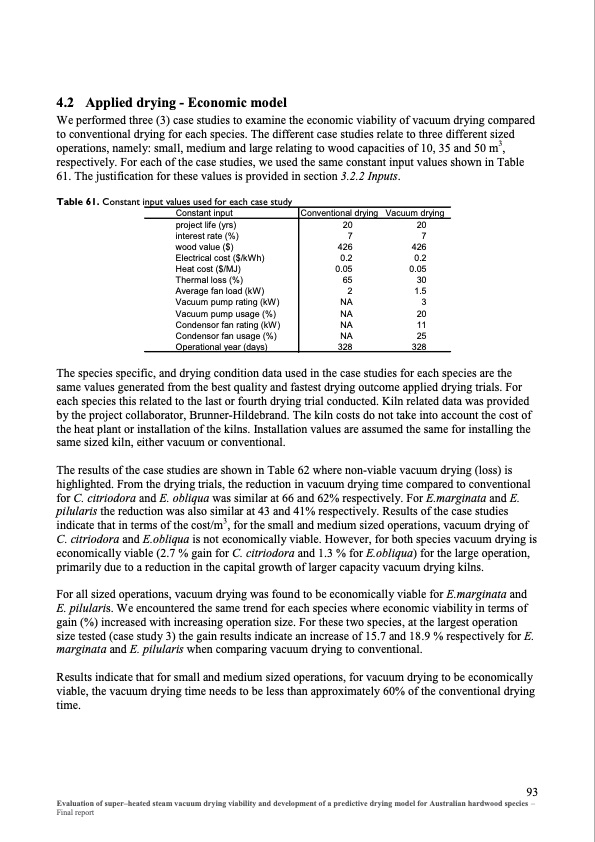

4.2 Applied drying - Economic model We performed three (3) case studies to examine the economic viability of vacuum drying compared to conventional drying for each species. The different case studies relate to three different sized operations, namely: small, medium and large relating to wood capacities of 10, 35 and 50 m3, respectively. For each of the case studies, we used the same constant input values shown in Table 61. The justification for these values is provided in section 3.2.2 Inputs. Table 61. Constant input values used for each case study Constant input Conventional project life (yrs) 20 interest rate (%) 7 wood value ($) 426 Electrical cost ($/kWh) 0.2 Heat cost ($/MJ) 0.05 Thermal loss (%) 65 Average fan load (kW) 2 Vacuum pump rating (kW) NA Vacuum pump usage (%) NA Condensor fan rating (kW) NA Condensor fan usage (%) NA Operational year (days) 328 drying Vacuum drying 20 7 426 0.2 0.05 30 1.5 3 20 11 25 328 The species specific, and drying condition data used in the case studies for each species are the same values generated from the best quality and fastest drying outcome applied drying trials. For each species this related to the last or fourth drying trial conducted. Kiln related data was provided by the project collaborator, Brunner-Hildebrand. The kiln costs do not take into account the cost of the heat plant or installation of the kilns. Installation values are assumed the same for installing the same sized kiln, either vacuum or conventional. The results of the case studies are shown in Table 62 where non-viable vacuum drying (loss) is highlighted. From the drying trials, the reduction in vacuum drying time compared to conventional for C. citriodora and E. obliqua was similar at 66 and 62% respectively. For E.marginata and E. pilularis the reduction was also similar at 43 and 41% respectively. Results of the case studies indicate that in terms of the cost/m3, for the small and medium sized operations, vacuum drying of C. citriodora and E.obliqua is not economically viable. However, for both species vacuum drying is economically viable (2.7 % gain for C. citriodora and 1.3 % for E.obliqua) for the large operation, primarily due to a reduction in the capital growth of larger capacity vacuum drying kilns. For all sized operations, vacuum drying was found to be economically viable for E.marginata and E. pilularis. We encountered the same trend for each species where economic viability in terms of gain (%) increased with increasing operation size. For these two species, at the largest operation size tested (case study 3) the gain results indicate an increase of 15.7 and 18.9 % respectively for E. marginata and E. pilularis when comparing vacuum drying to conventional. Results indicate that for small and medium sized operations, for vacuum drying to be economically viable, the vacuum drying time needs to be less than approximately 60% of the conventional drying time. 93 Evaluation of super–heated steam vacuum drying viability and development of a predictive drying model for Australian hardwood species – Final reportPDF Image | Evaluation of super-heated steam vacuum drying

PDF Search Title:

Evaluation of super-heated steam vacuum dryingOriginal File Name Searched:

PN08_2047_Vacuum_Drying_Reviewed_Report.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |