PDF Publication Title:

Text from PDF Page: 066

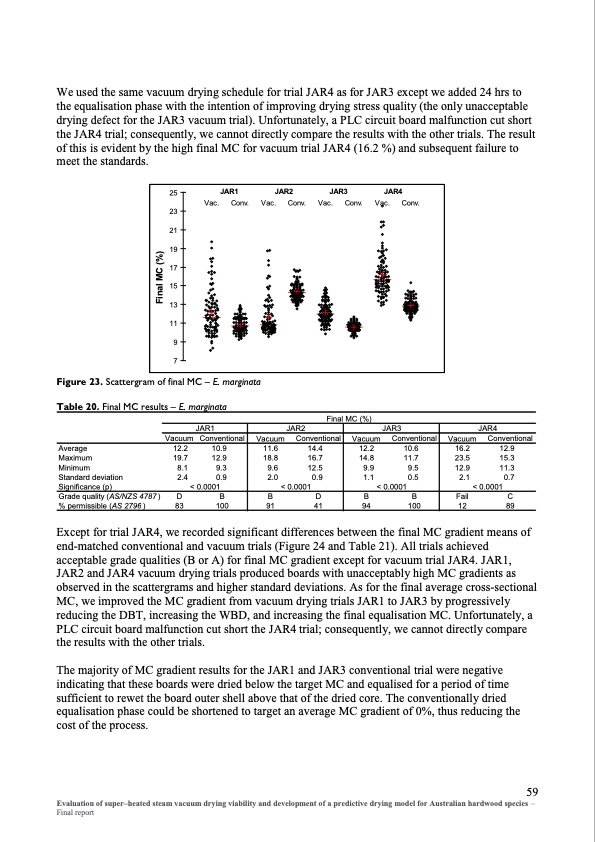

We used the same vacuum drying schedule for trial JAR4 as for JAR3 except we added 24 hrs to the equalisation phase with the intention of improving drying stress quality (the only unacceptable drying defect for the JAR3 vacuum trial). Unfortunately, a PLC circuit board malfunction cut short the JAR4 trial; consequently, we cannot directly compare the results with the other trials. The result of this is evident by the high final MC for vacuum trial JAR4 (16.2 %) and subsequent failure to meet the standards. 25 23 21 19 17 15 13 11 9 7 JAR1 Conv. JAR2 JAR3 JAR4 V ac . V ac . Conv. V ac . Conv. V ac . Conv. Figure 23. Scattergram of final MC – E. marginata Table 20. Final MC results – E. marginata JAR1 Vacuum Conventional 12.2 10.9 19.7 12.9 8.1 9.3 2.4 0.9 < 0.0001 D B 83 100 Final MC (%) JAR4 Vacuum Conventional JAR2 JAR3 Vacuum Conventional Vacuum Conventional 11.6 14.4 18.8 16.7 9.6 12.5 2.0 < 0.0001 0.9 12.2 10.6 14.8 11.7 9.9 1.1 < 0.0001 9.5 0.5 BD 91 41 BB 94 100 Average Maximum Minimum Standard deviation Significance (p) Grade quality (AS/NZS 4787 ) % permissible (AS 2796 ) 16.2 23.5 12.9 2.1 Fail 12 12.9 15.3 11.3 0.7 C 89 < 0.0001 Except for trial JAR4, we recorded significant differences between the final MC gradient means of end-matched conventional and vacuum trials (Figure 24 and Table 21). All trials achieved acceptable grade qualities (B or A) for final MC gradient except for vacuum trial JAR4. JAR1, JAR2 and JAR4 vacuum drying trials produced boards with unacceptably high MC gradients as observed in the scattergrams and higher standard deviations. As for the final average cross-sectional MC, we improved the MC gradient from vacuum drying trials JAR1 to JAR3 by progressively reducing the DBT, increasing the WBD, and increasing the final equalisation MC. Unfortunately, a PLC circuit board malfunction cut short the JAR4 trial; consequently, we cannot directly compare the results with the other trials. The majority of MC gradient results for the JAR1 and JAR3 conventional trial were negative indicating that these boards were dried below the target MC and equalised for a period of time sufficient to rewet the board outer shell above that of the dried core. The conventionally dried equalisation phase could be shortened to target an average MC gradient of 0%, thus reducing the cost of the process. 59 Evaluation of super–heated steam vacuum drying viability and development of a predictive drying model for Australian hardwood species – Final report Final MC (%)PDF Image | Evaluation of super-heated steam vacuum drying

PDF Search Title:

Evaluation of super-heated steam vacuum dryingOriginal File Name Searched:

PN08_2047_Vacuum_Drying_Reviewed_Report.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |