PDF Publication Title:

Text from PDF Page: 060

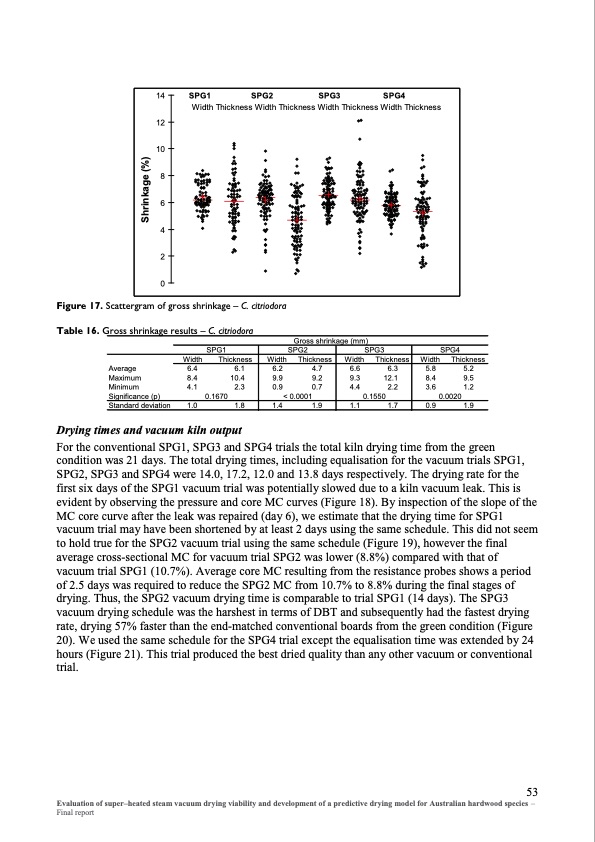

14 SPG1 SPG2 SPG3 SPG4 Width Thickness Width Thickness Width Thickness Width Thickness 12 10 8 6 4 2 0 Figure 17. Scattergram of gross shrinkage – C. citriodora Table 16. Gross shrinkage results – C. citriodora SPG1 Width Thickness Average 6.4 6.1 Maximum 8.4 10.4 Minimum 4.1 2.3 Significance (p) 0.1670 Standard deviation 1.0 1.8 Drying times and vacuum kiln output Gross shrinkage (mm) SPG4 Thickness SPG2 SPG3 Width Thickness Width Thickness 6.2 4.7 9.9 9.2 0.9 0.7 < 0.0001 6.6 6.3 9.3 12.1 4.4 0.1550 2.2 1.4 1.9 1.1 1.7 Width 5.8 8.4 3.6 5.2 9.5 1.2 1.9 0.9 0.0020 For the conventional SPG1, SPG3 and SPG4 trials the total kiln drying time from the green condition was 21 days. The total drying times, including equalisation for the vacuum trials SPG1, SPG2, SPG3 and SPG4 were 14.0, 17.2, 12.0 and 13.8 days respectively. The drying rate for the first six days of the SPG1 vacuum trial was potentially slowed due to a kiln vacuum leak. This is evident by observing the pressure and core MC curves (Figure 18). By inspection of the slope of the MC core curve after the leak was repaired (day 6), we estimate that the drying time for SPG1 vacuum trial may have been shortened by at least 2 days using the same schedule. This did not seem to hold true for the SPG2 vacuum trial using the same schedule (Figure 19), however the final average cross-sectional MC for vacuum trial SPG2 was lower (8.8%) compared with that of vacuum trial SPG1 (10.7%). Average core MC resulting from the resistance probes shows a period of 2.5 days was required to reduce the SPG2 MC from 10.7% to 8.8% during the final stages of drying. Thus, the SPG2 vacuum drying time is comparable to trial SPG1 (14 days). The SPG3 vacuum drying schedule was the harshest in terms of DBT and subsequently had the fastest drying rate, drying 57% faster than the end-matched conventional boards from the green condition (Figure 20). We used the same schedule for the SPG4 trial except the equalisation time was extended by 24 hours (Figure 21). This trial produced the best dried quality than any other vacuum or conventional trial. 53 Evaluation of super–heated steam vacuum drying viability and development of a predictive drying model for Australian hardwood species – Final report Shrinkage (%)PDF Image | Evaluation of super-heated steam vacuum drying

PDF Search Title:

Evaluation of super-heated steam vacuum dryingOriginal File Name Searched:

PN08_2047_Vacuum_Drying_Reviewed_Report.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |