PDF Publication Title:

Text from PDF Page: 058

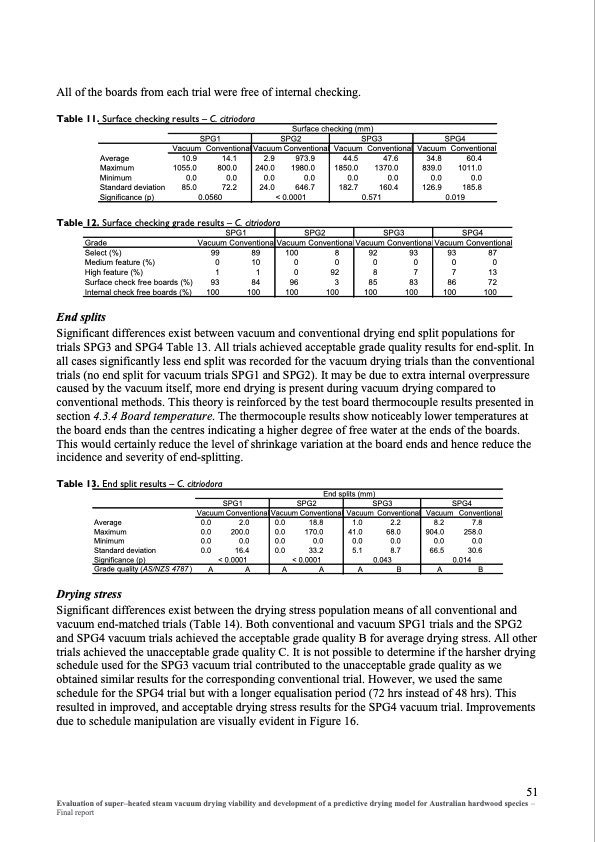

All of the boards from each trial were free of internal checking. Table 11. Surface checking results – C. citriodora Surface checking (mm) SPG1 Vacuum ConventionalVacuum ConventionalVacuum ConventionalVacuum Conventional SPG2 SPG3 Vacuum Conventional Vacuum Conventional 2.9 240.0 0.0 24.0 973.9 1980.0 0.0 646.7 < 0.0001 44.5 47.6 1850.0 1370.0 0.0 0.0 182.7 160.4 0.571 Average Maximum Minimum Standard deviation Significance (p) SPG1 Vacuum Conventional 10.9 14.1 1055.0 800.0 0.0 0.0 85.0 72.2 0.0560 SPG4 Vacuum Conventional 34.8 60.4 839.0 1011.0 0.0 0.0 126.9 185.8 0.019 Table 12. Surface checking grade results – C. citriodora SPG2 SPG3 SPG4 Grade Select (%) Medium feature (%) High feature (%) Surface check free boards (%) Internal check free boards (%) End splits 99 89 0 10 1 1 93 84 100 100 93 87 0 0 7 13 86 72 100 100 100 8 00 0 92 96 3 100 100 92 93 00 87 85 83 100 100 Significant differences exist between vacuum and conventional drying end split populations for trials SPG3 and SPG4 Table 13. All trials achieved acceptable grade quality results for end-split. In all cases significantly less end split was recorded for the vacuum drying trials than the conventional trials (no end split for vacuum trials SPG1 and SPG2). It may be due to extra internal overpressure caused by the vacuum itself, more end drying is present during vacuum drying compared to conventional methods. This theory is reinforced by the test board thermocouple results presented in section 4.3.4 Board temperature. The thermocouple results show noticeably lower temperatures at the board ends than the centres indicating a higher degree of free water at the ends of the boards. This would certainly reduce the level of shrinkage variation at the board ends and hence reduce the incidence and severity of end-splitting. Table 13. End split results – C. citriodora End splits (mm) SPG1 Vacuum Conventional 0.0 2.0 0.0 200.0 0.0 0.0 0.0 16.4 < 0.0001 A A SPG4 SPG2 SPG3 Vacuum Conventional Vacuum Conventional 0.0 18.8 0.0 170.0 0.0 0.0 0.0 33.2 < 0.0001 1.0 2.2 41.0 68.0 0.0 0.0 5.1 8.7 0.043 AA AB Average Maximum Minimum Standard deviation Significance (p) Grade quality (AS/NZS 4787 ) Drying stress Vacuum 8.2 904.0 0.0 66.5 A Conventional 7.8 258.0 0.0 30.6 0.014 B Significant differences exist between the drying stress population means of all conventional and vacuum end-matched trials (Table 14). Both conventional and vacuum SPG1 trials and the SPG2 and SPG4 vacuum trials achieved the acceptable grade quality B for average drying stress. All other trials achieved the unacceptable grade quality C. It is not possible to determine if the harsher drying schedule used for the SPG3 vacuum trial contributed to the unacceptable grade quality as we obtained similar results for the corresponding conventional trial. However, we used the same schedule for the SPG4 trial but with a longer equalisation period (72 hrs instead of 48 hrs). This resulted in improved, and acceptable drying stress results for the SPG4 vacuum trial. Improvements due to schedule manipulation are visually evident in Figure 16. 51 Evaluation of super–heated steam vacuum drying viability and development of a predictive drying model for Australian hardwood species – Final reportPDF Image | Evaluation of super-heated steam vacuum drying

PDF Search Title:

Evaluation of super-heated steam vacuum dryingOriginal File Name Searched:

PN08_2047_Vacuum_Drying_Reviewed_Report.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |