PDF Publication Title:

Text from PDF Page: 041

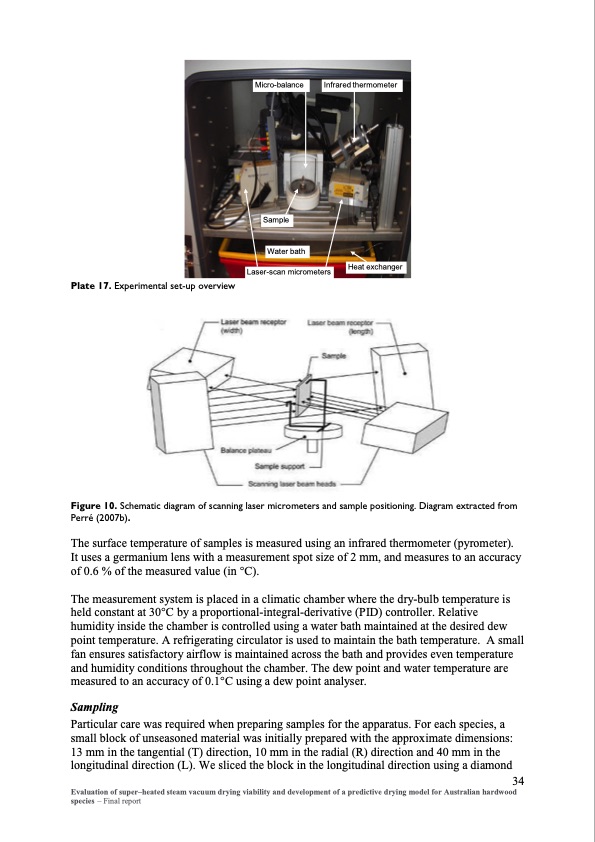

Micro-balance Infrared thermometer Sample Water bath Laser-scan micrometers Heat exchanger Plate 17. Experimental set-up overview Figure 10. Schematic diagram of scanning laser micrometers and sample positioning. Diagram extracted from Perré (2007b). The surface temperature of samples is measured using an infrared thermometer (pyrometer). It uses a germanium lens with a measurement spot size of 2 mm, and measures to an accuracy of 0.6 % of the measured value (in °C). The measurement system is placed in a climatic chamber where the dry-bulb temperature is held constant at 30°C by a proportional-integral-derivative (PID) controller. Relative humidity inside the chamber is controlled using a water bath maintained at the desired dew point temperature. A refrigerating circulator is used to maintain the bath temperature. A small fan ensures satisfactory airflow is maintained across the bath and provides even temperature and humidity conditions throughout the chamber. The dew point and water temperature are measured to an accuracy of 0.1°C using a dew point analyser. Sampling Particular care was required when preparing samples for the apparatus. For each species, a small block of unseasoned material was initially prepared with the approximate dimensions: 13 mm in the tangential (T) direction, 10 mm in the radial (R) direction and 40 mm in the longitudinal direction (L). We sliced the block in the longitudinal direction using a diamond 34 Evaluation of super–heated steam vacuum drying viability and development of a predictive drying model for Australian hardwood species – Final reportPDF Image | Evaluation of super-heated steam vacuum drying

PDF Search Title:

Evaluation of super-heated steam vacuum dryingOriginal File Name Searched:

PN08_2047_Vacuum_Drying_Reviewed_Report.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |