PDF Publication Title:

Text from PDF Page: 016

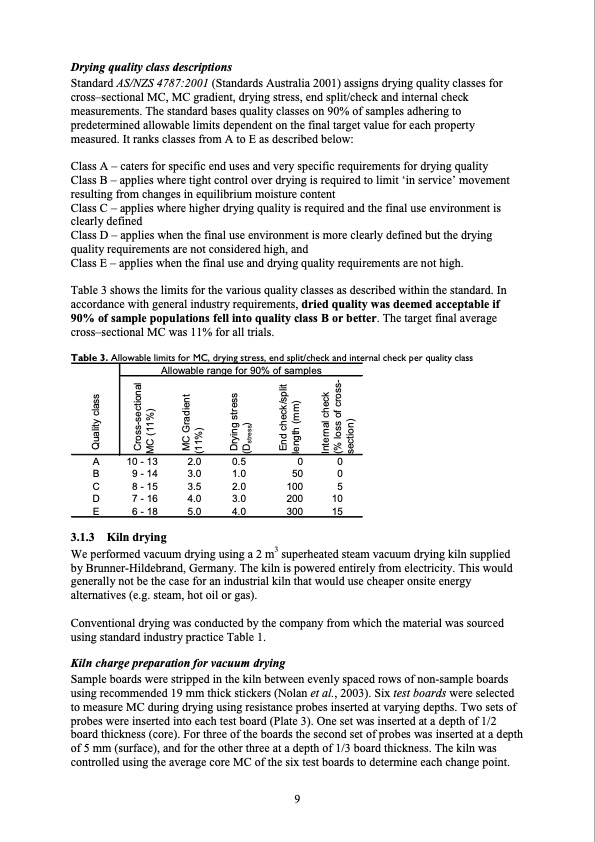

Drying quality class descriptions Standard AS/NZS 4787:2001 (Standards Australia 2001) assigns drying quality classes for cross–sectional MC, MC gradient, drying stress, end split/check and internal check measurements. The standard bases quality classes on 90% of samples adhering to predetermined allowable limits dependent on the final target value for each property measured. It ranks classes from A to E as described below: Class A – caters for specific end uses and very specific requirements for drying quality Class B – applies where tight control over drying is required to limit ‘in service’ movement resulting from changes in equilibrium moisture content Class C – applies where higher drying quality is required and the final use environment is clearly defined Class D – applies when the final use environment is more clearly defined but the drying quality requirements are not considered high, and Class E – applies when the final use and drying quality requirements are not high. Table 3 shows the limits for the various quality classes as described within the standard. In accordance with general industry requirements, dried quality was deemed acceptable if 90% of sample populations fell into quality class B or better. The target final average cross–sectional MC was 11% for all trials. Table 3. Allowable limits for MC, drying stress, end split/check and internal check per quality class Allowable range for 90% of samples A 10-13 2.0 B 9-14 3.0 C 8-15 3.5 D 7-16 4.0 E 6-18 5.0 3.1.3 Kiln drying 0.5 0 0 1.0 50 0 2.0 100 5 3.0 200 10 4.0 300 15 We performed vacuum drying using a 2 m3 superheated steam vacuum drying kiln supplied by Brunner-Hildebrand, Germany. The kiln is powered entirely from electricity. This would generally not be the case for an industrial kiln that would use cheaper onsite energy alternatives (e.g. steam, hot oil or gas). Conventional drying was conducted by the company from which the material was sourced using standard industry practice Table 1. Kiln charge preparation for vacuum drying Sample boards were stripped in the kiln between evenly spaced rows of non-sample boards using recommended 19 mm thick stickers (Nolan et al., 2003). Six test boards were selected to measure MC during drying using resistance probes inserted at varying depths. Two sets of probes were inserted into each test board (Plate 3). One set was inserted at a depth of 1/2 board thickness (core). For three of the boards the second set of probes was inserted at a depth of 5 mm (surface), and for the other three at a depth of 1/3 board thickness. The kiln was controlled using the average core MC of the six test boards to determine each change point. 9 Quality class Cross-sectional MC (11%) MC Gradient (11%) Drying stress (Dstress) End check/split length (mm) Internal check (% loss of cross- section)PDF Image | Evaluation of super-heated steam vacuum drying

PDF Search Title:

Evaluation of super-heated steam vacuum dryingOriginal File Name Searched:

PN08_2047_Vacuum_Drying_Reviewed_Report.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |