PDF Publication Title:

Text from PDF Page: 011

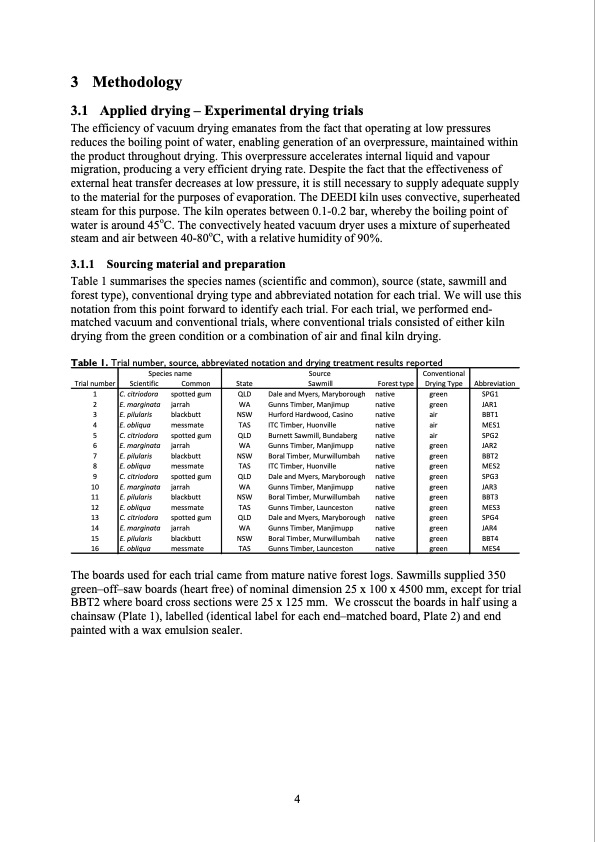

3 Methodology 3.1 Applied drying – Experimental drying trials The efficiency of vacuum drying emanates from the fact that operating at low pressures reduces the boiling point of water, enabling generation of an overpressure, maintained within the product throughout drying. This overpressure accelerates internal liquid and vapour migration, producing a very efficient drying rate. Despite the fact that the effectiveness of external heat transfer decreases at low pressure, it is still necessary to supply adequate supply to the material for the purposes of evaporation. The DEEDI kiln uses convective, superheated steam for this purpose. The kiln operates between 0.1-0.2 bar, whereby the boiling point of water is around 45oC. The convectively heated vacuum dryer uses a mixture of superheated steam and air between 40-80oC, with a relative humidity of 90%. 3.1.1 Sourcing material and preparation Table 1 summarises the species names (scientific and common), source (state, sawmill and forest type), conventional drying type and abbreviated notation for each trial. We will use this notation from this point forward to identify each trial. For each trial, we performed end- matched vacuum and conventional trials, where conventional trials consisted of either kiln drying from the green condition or a combination of air and final kiln drying. Table 1. Trial number, source, abbreviated notation and drying treatment results reported Species name Scientific Common Source State Sawmill Forest type Conventional Drying Type C. citriodora E. marginata E. pilularis E. obliqua C. citriodora E. marginata E. pilularis E. obliqua C. citriodora E. marginata E. pilularis E. obliqua C. citriodora E. marginata E. pilularis E. obliqua spotted gum jarrah blackbutt messmate spotted gum jarrah blackbutt messmate spotted gum jarrah blackbutt messmate spotted gum jarrah blackbutt messmate QLD Dale and Myers, Maryborough WA Gunns Timber, Manjimup NSW Hurford Hardwood, Casino TAS ITC Timber, Huonville QLD Burnett Sawmill, Bundaberg WA Gunns Timber, Manjimupp NSW Boral Timber, Murwillumbah TAS ITC Timber, Huonville QLD Dale and Myers, Maryborough WA Gunns Timber, Manjimupp NSW Boral Timber, Murwillumbah TAS Gunns Timber, Launceston QLD Dale and Myers, Maryborough WA Gunns Timber, Manjimupp NSW Boral Timber, Murwillumbah TAS Gunns Timber, Launceston native native native native native native native native native native native native native native native native green green air air air green green green green green green green green green green green Trial number 1 SPG1 2 JAR1 3 BBT1 4 MES1 5 SPG2 6 JAR2 7 BBT2 8 MES2 9 SPG3 10 JAR3 11 BBT3 12 MES3 13 SPG4 14 JAR4 15 BBT4 16 MES4 The boards used for each trial came from mature native forest logs. Sawmills supplied 350 green–off–saw boards (heart free) of nominal dimension 25 x 100 x 4500 mm, except for trial BBT2 where board cross sections were 25 x 125 mm. We crosscut the boards in half using a chainsaw (Plate 1), labelled (identical label for each end–matched board, Plate 2) and end painted with a wax emulsion sealer. Abbreviation 4PDF Image | Evaluation of super-heated steam vacuum drying

PDF Search Title:

Evaluation of super-heated steam vacuum dryingOriginal File Name Searched:

PN08_2047_Vacuum_Drying_Reviewed_Report.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |