PDF Publication Title:

Text from PDF Page: 005

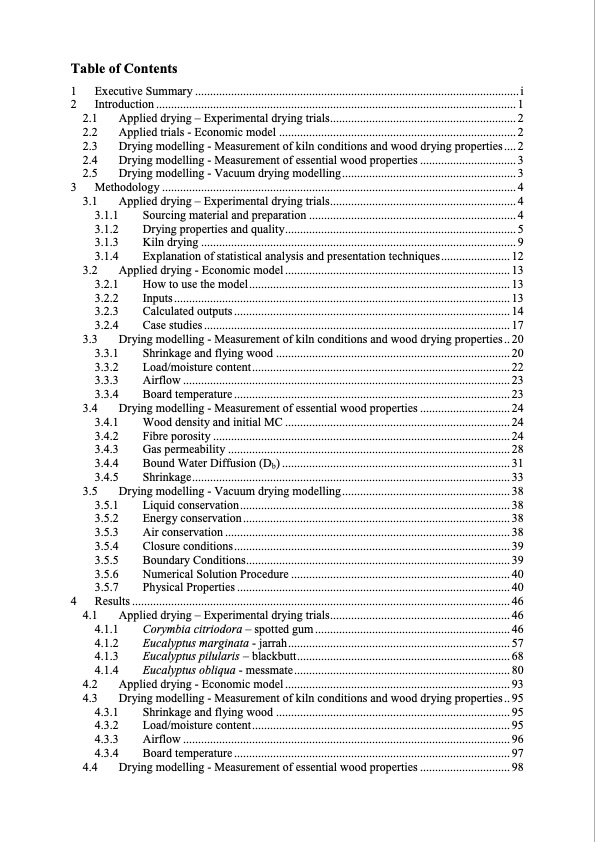

Table of Contents 1 2 3 Executive Summary ............................................................................................................ i Introduction ........................................................................................................................ 1 2.1 Applied drying – Experimental drying trials.............................................................. 2 2.2 Applied trials - Economic model ............................................................................... 2 2.3 Drying modelling - Measurement of kiln conditions and wood drying properties .... 2 2.4 Drying modelling - Measurement of essential wood properties ................................ 3 2.5 Drying modelling - Vacuum drying modelling.......................................................... 3 Methodology ...................................................................................................................... 4 3.1 Applied drying – Experimental drying trials.............................................................. 4 3.1.1 Sourcing material and preparation ..................................................................... 4 3.1.2 Drying properties and quality............................................................................. 5 3.1.3 Kiln drying ......................................................................................................... 9 3.1.4 Explanation of statistical analysis and presentation techniques ....................... 12 3.2 Applied drying - Economic model ........................................................................... 13 3.2.1 How to use the model....................................................................................... 13 3.2.2 Inputs ................................................................................................................ 13 3.2.3 Calculated outputs ............................................................................................ 14 3.2.4 Case studies ...................................................................................................... 17 3.3 Drying modelling - Measurement of kiln conditions and wood drying properties .. 20 3.3.1 Shrinkage and flying wood .............................................................................. 20 3.3.2 Load/moisture content...................................................................................... 22 3.3.3 Airflow ............................................................................................................. 23 3.3.4 Board temperature ............................................................................................ 23 3.4 Drying modelling - Measurement of essential wood properties .............................. 24 3.4.1 Wood density and initial MC ........................................................................... 24 3.4.2 Fibre porosity ................................................................................................... 24 4 3.5 Drying modelling - Vacuum drying modelling........................................................ 38 3.5.1 Liquid conservation.......................................................................................... 38 3.5.2 Energy conservation ......................................................................................... 38 3.5.3 Air conservation ............................................................................................... 38 3.5.4 Closure conditions ............................................................................................ 39 3.5.5 Boundary Conditions........................................................................................ 39 3.5.6 Numerical Solution Procedure ......................................................................... 40 3.5.7 Physical Properties ........................................................................................... 40 Results .............................................................................................................................. 46 4.1 Applied drying – Experimental drying trials............................................................ 46 4.1.1 Corymbia citriodora – spotted gum ................................................................. 46 4.1.2 Eucalyptus marginata - jarrah .......................................................................... 57 4.1.3 Eucalyptus pilularis – blackbutt....................................................................... 68 4.1.4 Eucalyptus obliqua - messmate........................................................................ 80 4.2 Applied drying - Economic model ........................................................................... 93 4.3 Drying modelling - Measurement of kiln conditions and wood drying properties .. 95 4.3.1 Shrinkage and flying wood .............................................................................. 95 4.3.2 Load/moisture content...................................................................................... 95 4.3.3 Airflow ............................................................................................................. 96 4.3.4 Board temperature ............................................................................................ 97 4.4 Drying modelling - Measurement of essential wood properties .............................. 98 3.4.3 3.4.4 3.4.5 Gas permeability .............................................................................................. 28 Bound Water Diffusion (Db) ............................................................................ 31 Shrinkage.......................................................................................................... 33PDF Image | Evaluation of super-heated steam vacuum drying

PDF Search Title:

Evaluation of super-heated steam vacuum dryingOriginal File Name Searched:

PN08_2047_Vacuum_Drying_Reviewed_Report.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |