PDF Publication Title:

Text from PDF Page: 006

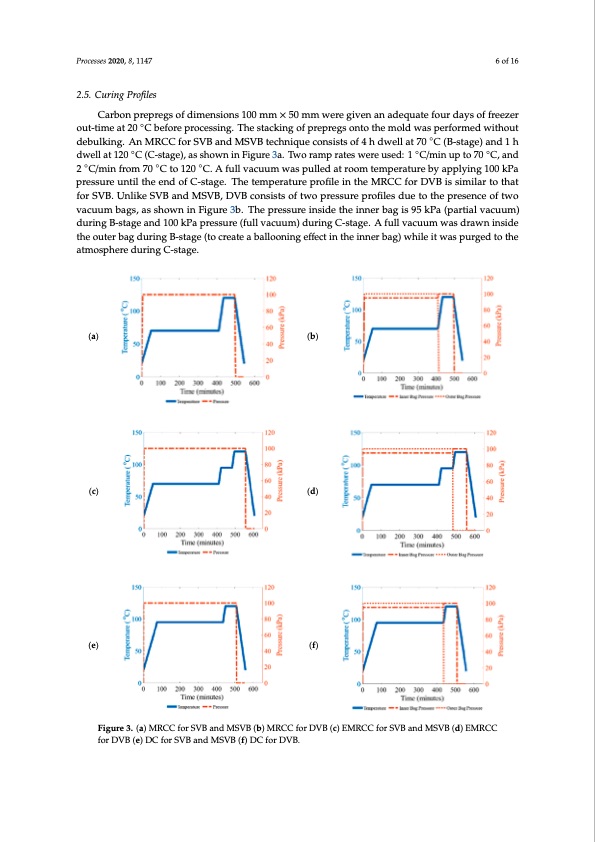

Processes 2020, 8, x FOR PEER REVIEW 6 of 16 kPa pressure until the end of C-stage. The temperature profile in the MRCC for DVB is similar to that for SVB. Unlike SVB and MSVB, DVB consists of two pressure profiles due to the presence of two vacuum bags, as shown in Figure 3b. The pressure inside the inner bag is 95 kPa (partial vacuum) Processes 2020, 8, 1147 6 of 16 during B-stage and 100 kPa pressure (full vacuum) during C-stage. A full vacuum was drawn inside the outer bag during B-stage (to create a ballooning effect in the inner bag) while it was purged to the atmosphere during C-stage. 2.5. Curing Profiles EMRCC profile was determined by differential scanning calorimetry (DSC) Q2000 V24. The Carbon prepregs of dimensions 100 mm × 50 mm were given an adequate four days of freezer glass transition temperature (Tg) was determined to indicate a low degree of cure for uncured resin. out-time at 20 ◦C before processing. The stacking of prepregs onto the mold was performed without Hence, EMRCC for SVB and DVB techniques was formulated by incorporating an additional one debulking. An MRCC for SVB and MSVB technique consists of 4 h dwell at 70 ◦C (B-stage) and 1 h hour dwell at 95 °C with a ramp rate of 2 °C/min. EMRCC for SVB and MSVB techniques are shown dwell at 120 ◦C (C-stage), as shown in Figure 3a. Two ramp rates were used: 1 ◦C/min up to 70 ◦C, and in Figure 3c with a single pressure profile (for a single bag). Figure 3d indicates two pressure profiles 2 ◦C/min from 70 ◦C to 120 ◦C. A full vacuum was pulled at room temperature by applying 100 kPa for inner and outer bags used in DVB, whereas the temperature profile is identical in both SVB/MSVB pressure until the end of C-stage. The temperature profile in the MRCC for DVB is similar to that and DVB techniques. For DC, the first dwell temperature was set to 95 °C instead of the recommended for SVB. Unlike SVB and MSVB, DVB consists of two pressure profiles due to the presence of two 70 °C (as in MRCC) for 6 h for both SVB and DVB. DC for SVB and MSVB techniques are shown in vacuum bags, as shown in Figure 3b. The pressure inside the inner bag is 95 kPa (partial vacuum) Figure 3e with a single pressure profile (for a single bag) and Figure 3f indicates two pressure profiles during B-stage and 100 kPa pressure (full vacuum) during C-stage. A full vacuum was drawn inside for inner and outer bags used in DVB, whereas the temperature profile is identical in both SVB/MSVB the outer bag during B-stage (to create a ballooning effect in the inner bag) while it was purged to the and DVB techniques. atmosphere during C-stage. (a) (b) (c) (d) (e) (f) Figure 3. (a) MRCC for SVB and MSVB (b) MRCC for DVB (c) EMRCC for SVB and MSVB (d) EMRCC for DVB (e) DC for SVB and MSVB (f) DC for DVB.PDF Image | Effects of Processing Parameters for Vacuum-Bagging

PDF Search Title:

Effects of Processing Parameters for Vacuum-BaggingOriginal File Name Searched:

processes-08-01147.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |