PDF Publication Title:

Text from PDF Page: 140

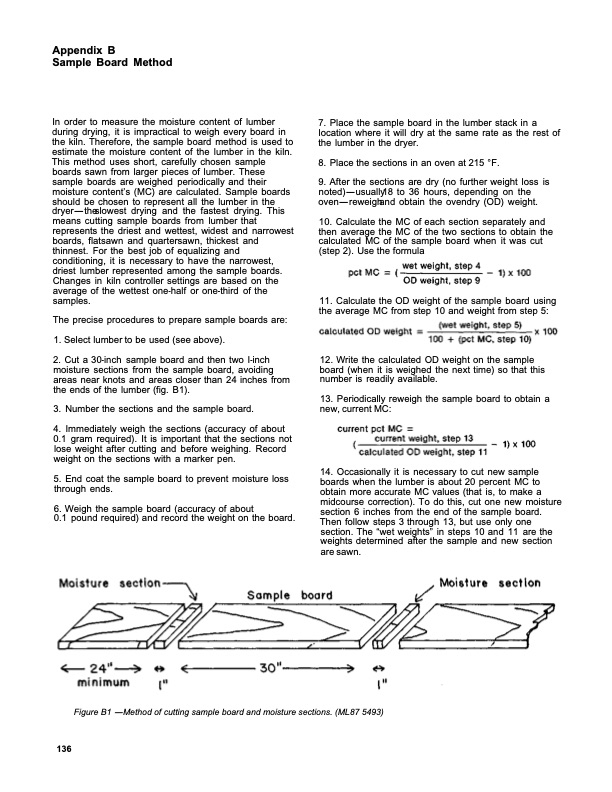

Appendix B Sample Board Method In order to measure the moisture content of lumber during drying, it is impractical to weigh every board in the kiln. Therefore, the sample board method is used to estimate the moisture content of the lumber in the kiln. This method uses short, carefully chosen sample boards sawn from larger pieces of lumber. These sample boards are weighed periodically and their moisture content’s (MC) are calculated. Sample boards should be chosen to represent all the lumber in the dryer- theslowest drying and the fastest drying. This means cutting sample boards from lumber that represents the driest and wettest, widest and narrowest boards, flatsawn and quartersawn, thickest and thinnest. For the best job of equalizing and conditioning, it is necessary to have the narrowest, driest lumber represented among the sample boards. Changes in kiln controller settings are based on the average of the wettest one-half or one-third of the samples. The precise procedures to prepare sample boards are: 1. Select lumber to be used (see above). 2. Cut a 30-inch sample board and then two I-inch moisture sections from the sample board, avoiding areas near knots and areas closer than 24 inches from the ends of the lumber (fig. B1). 3. Number the sections and the sample board. 4. Immediately weigh the sections (accuracy of about 0.1 gram required). It is important that the sections not lose weight after cutting and before weighing. Record weight on the sections with a marker pen. 5. End coat the sample board to prevent moisture loss through ends. 6. Weigh the sample board (accuracy of about 0.1 pound required) and record the weight on the board. 7. Place the sample board in the lumber stack in a location where it will dry at the same rate as the rest of the lumber in the dryer. 8. Place the sections in an oven at 215 °F. 9. After the sections are dry (no further weight loss is noted)- usually18 to 36 hours, depending on the oven- reweighand obtain the ovendry (OD) weight. 10. Calculate the MC of each section separately and then average the MC of the two sections to obtain the calculated MC of the sample board when it was cut (step 2). Use the formula 11. Calculate the OD weight of the sample board using the average MC from step 10 and weight from step 5: 12. Write the calculated OD weight on the sample board (when it is weighed the next time) so that this number is readily available. 13. Periodically reweigh the sample board to obtain a new, current MC: 14. Occasionally it is necessary to cut new sample boards when the lumber is about 20 percent MC to obtain more accurate MC values (that is, to make a midcourse correction). To do this, cut one new moisture section 6 inches from the end of the sample board. Then follow steps 3 through 13, but use only one section. The “wet weights” in steps 10 and 11 are the weights determined after the sample and new section are sawn. 136 Figure B1 - Method of cutting sample board and moisture sections. (ML87 5493)PDF Image | Dry Kiln Schedules FPL GTR 57

PDF Search Title:

Dry Kiln Schedules FPL GTR 57Original File Name Searched:

DryKilnSchedulesForCommercialWoods.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |