PDF Publication Title:

Text from PDF Page: 009

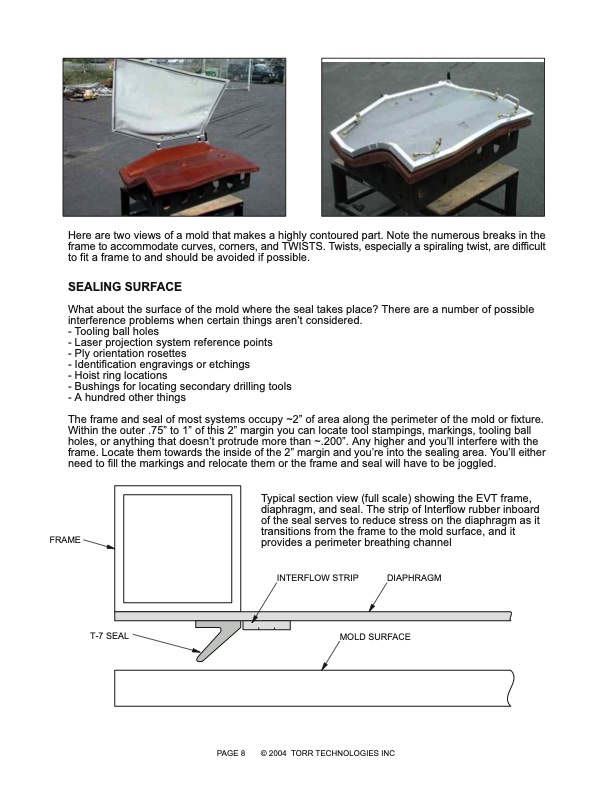

FRAME Typical section view (full scale) showing the EVT frame, diaphragm, and seal. The strip of Interflow rubber inboard of the seal serves to reduce stress on the diaphragm as it transitions from the frame to the mold surface, and it provides a perimeter breathing channel INTERFLOW STRIP DIAPHRAGM MOLD SURFACE Here are two views of a mold that makes a highly contoured part. Note the numerous breaks in the frame to accommodate curves, corners, and TWISTS. Twists, especially a spiraling twist, are difficult to fit a frame to and should be avoided if possible. SEALING SURFACE What about the surface of the mold where the seal takes place? There are a number of possible interference problems when certain things aren’t considered. - Tooling ball holes - Laser projection system reference points - Ply orientation rosettes - Identification engravings or etchings - Hoist ring locations - Bushings for locating secondary drilling tools - A hundred other things The frame and seal of most systems occupy ~2” of area along the perimeter of the mold or fixture. Within the outer .75” to 1” of this 2” margin you can locate tool stampings, markings, tooling ball holes, or anything that doesn’t protrude more than ~.200”. Any higher and you’ll interfere with the frame. Locate them towards the inside of the 2” margin and you’re into the sealing area. You’ll either need to fill the markings and relocate them or the frame and seal will have to be joggled. T-7 SEAL PAGE 8 © 2004 TORR TECHNOLOGIES INCPDF Image | DESIGNING MOLDS AND FIXTURES Vacuum Bagging

PDF Search Title:

DESIGNING MOLDS AND FIXTURES Vacuum BaggingOriginal File Name Searched:

TorrMDG.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |