PDF Publication Title:

Text from PDF Page: 006

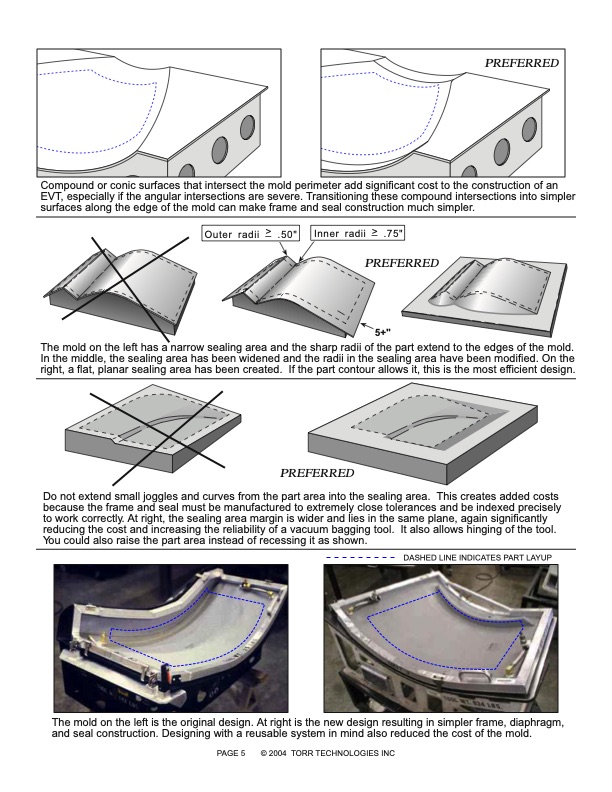

PREFERRED Compound or conic surfaces that intersect the mold perimeter add significant cost to the construction of an EVT, especially if the angular intersections are severe. Transitioning these compound intersections into simpler surfaces along the edge of the mold can make frame and seal construction much simpler. Outer radii _> .50" Inner radii >_ .75" PREFERRED 5+" The mold on the left has a narrow sealing area and the sharp radii of the part extend to the edges of the mold. In the middle, the sealing area has been widened and the radii in the sealing area have been modified. On the right, a flat, planar sealing area has been created. If the part contour allows it, this is the most efficient design. PREFERRED Do not extend small joggles and curves from the part area into the sealing area. This creates added costs because the frame and seal must be manufactured to extremely close tolerances and be indexed precisely to work correctly. At right, the sealing area margin is wider and lies in the same plane, again significantly reducing the cost and increasing the reliability of a vacuum bagging tool. It also allows hinging of the tool. You could also raise the part area instead of recessing it as shown. DASHED LINE INDICATES PART LAYUP The mold on the left is the original design. At right is the new design resulting in simpler frame, diaphragm, and seal construction. Designing with a reusable system in mind also reduced the cost of the mold. PAGE 5 © 2004 TORR TECHNOLOGIES INCPDF Image | DESIGNING MOLDS AND FIXTURES Vacuum Bagging

PDF Search Title:

DESIGNING MOLDS AND FIXTURES Vacuum BaggingOriginal File Name Searched:

TorrMDG.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |