PDF Publication Title:

Text from PDF Page: 005

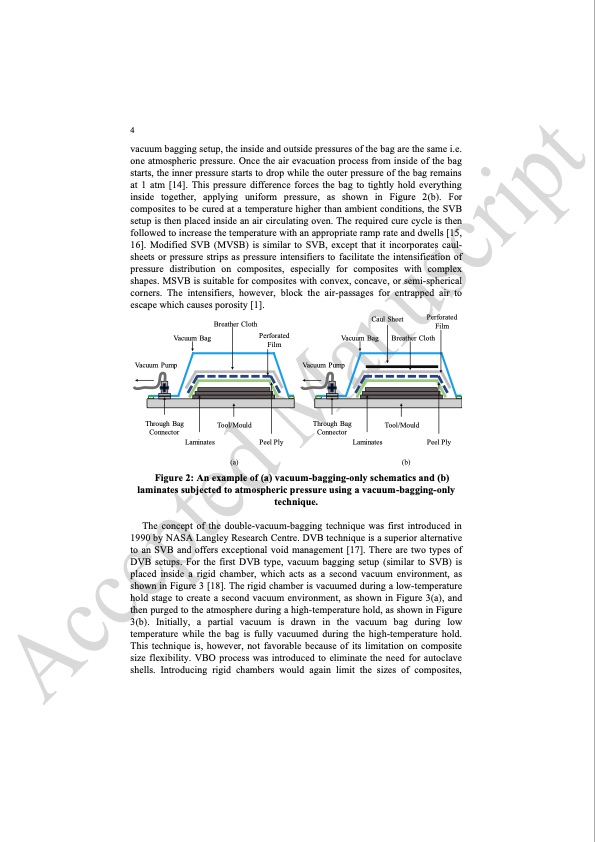

4 vacuum bagging setup, the inside and outside pressures of the bag are the same i.e. one atmospheric pressure. Once the air evacuation process from inside of the bag starts, the inner pressure starts to drop while the outer pressure of the bag remains at 1 atm [14]. This pressure difference forces the bag to tightly hold everything inside together, applying uniform pressure, as shown in Figure 2(b). For composites to be cured at a temperature higher than ambient conditions, the SVB setup is then placed inside an air circulating oven. The required cure cycle is then followed to increase the temperature with an appropriate ramp rate and dwells [15, 16]. Modified SVB (MVSB) is similar to SVB, except that it incorporates caul- sheets or pressure strips as pressure intensifiers to facilitate the intensification of pressure distribution on composites, especially for composites with complex shapes. MSVB is suitable for composites with convex, concave, or semi-spherical corners. The intensifiers, however, block the air-passages for entrapped air to escape which causes porosity [1]. Breather Cloth Film Tool/Mould (a) Caul Sheet Perforated Film Vacuum Bag Vacuum Pump Through Bag Connector Perforated Vacuum Bag Vacuum Pump Through Bag Connector Laminates Figure 2: An example of (a) vacuum-bagging-only schematics and (b) laminates subjected to atmospheric pressure using a vacuum-bagging-only technique. The concept of the double-vacuum-bagging technique was first introduced in 1990 by NASA Langley Research Centre. DVB technique is a superior alternative to an SVB and offers exceptional void management [17]. There are two types of DVB setups. For the first DVB type, vacuum bagging setup (similar to SVB) is placed inside a rigid chamber, which acts as a second vacuum environment, as shown in Figure 3 [18]. The rigid chamber is vacuumed during a low-temperature hold stage to create a second vacuum environment, as shown in Figure 3(a), and then purged to the atmosphere during a high-temperature hold, as shown in Figure 3(b). Initially, a partial vacuum is drawn in the vacuum bag during low temperature while the bag is fully vacuumed during the high-temperature hold. This technique is, however, not favorable because of its limitation on composite size flexibility. VBO process was introduced to eliminate the need for autoclave shells. Introducing rigid chambers would again limit the sizes of composites, Laminates Peel Ply Breather Cloth Tool/Mould (b) Peel PlyPDF Image | Comparison of Single-Vacuum-Bag and Double-Vacuum-Bag Methods

PDF Search Title:

Comparison of Single-Vacuum-Bag and Double-Vacuum-Bag MethodsOriginal File Name Searched:

1912176.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |