PDF Publication Title:

Text from PDF Page: 006

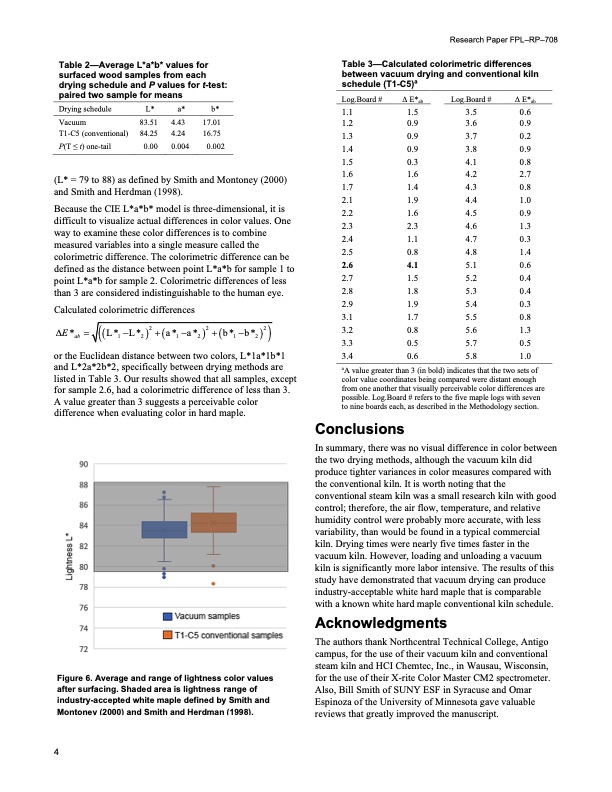

Research Paper FPL–RP–708 Table 3—Calculated colorimetric differences between vacuum drying and conventional kiln schedule (T1-C5)a Log.Board # 1.1 1.2 1.3 1.4 1.5 1.6 1.7 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 3.1 3.2 3.3 3.4 Δ E*ab 1.5 0.9 0.9 0.9 0.3 1.6 1.4 1.9 1.6 2.3 1.1 0.8 4.1 1.5 1.8 1.9 1.7 0.8 0.5 0.6 Log.Board # 3.5 3.6 3.7 3.8 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 5.1 5.2 5.3 5.4 5.5 5.6 5.7 5.8 Δ E*ab 0.6 0.9 0.2 0.9 0.8 2.7 0.8 1.0 0.9 1.3 0.3 1.4 0.6 0.4 0.4 0.3 0.8 1.3 0.5 1.0 aA value greater than 3 (in bold) indicates that the two sets of color value coordinates being compared were distant enough from one another that visually perceivable color differences are possible. Log.Board # refers to the five maple logs with seven to nine boards each, as described in the Methodology section. Table 2—Average L*a*b* values for surfaced wood samples from each drying schedule and P values for t-test: paired two sample for means Drying schedule Vacuum T1-C5 (conventional) P(T ≤ t) one-tail L* a* 83.51 4.43 84.25 4.24 0.00 0.004 b* 17.01 16.75 0.002 (L* = 79 to 88) as defined by Smith and Montoney (2000) and Smith and Herdman (1998). Because the CIE L*a*b* model is three-dimensional, it is difficult to visualize actual differences in color values. One way to examine these color differences is to combine measured variables into a single measure called the colorimetric difference. The colorimetric difference can be defined as the distance between point L*a*b for sample 1 to point L*a*b for sample 2. Colorimetric differences of less than 3 are considered indistinguishable to the human eye. Calculated colorimetric differences ∆ E * = ( ( L * L −* ) 2 ( a+ * a *− ) 2 ( b+ * b *− ) 2 ) or the Euclidean distance between two colors, L*1a*1b*1 and L*2a*2b*2, specifically between drying methods are listed in Table 3. Our results showed that all samples, except for sample 2.6, had a colorimetric difference of less than 3. A value greater than 3 suggests a perceivable color difference when evaluating color in hard maple. ab 121212 Conclusions In summary, there was no visual difference in color between the two drying methods, although the vacuum kiln did produce tighter variances in color measures compared with the conventional kiln. It is worth noting that the conventional steam kiln was a small research kiln with good control; therefore, the air flow, temperature, and relative humidity control were probably more accurate, with less variability, than would be found in a typical commercial kiln. Drying times were nearly five times faster in the vacuum kiln. However, loading and unloading a vacuum kiln is significantly more labor intensive. The results of this study have demonstrated that vacuum drying can produce industry-acceptable white hard maple that is comparable with a known white hard maple conventional kiln schedule. Acknowledgments The authors thank Northcentral Technical College, Antigo campus, for the use of their vacuum kiln and conventional steam kiln and HCI Chemtec, Inc., in Wausau, Wisconsin, for the use of their X-rite Color Master CM2 spectrometer. Also, Bill Smith of SUNY ESF in Syracuse and Omar Espinoza of the University of Minnesota gave valuable reviews that greatly improved the manuscript. Figure 6. Average and range of lightness color values after surfacing. Shaded area is lightness range of industry-accepted white maple defined by Smith and Montoney (2000) and Smith and Herdman (1998). 4PDF Image | Comparing Vacuum Drying and Conventional Drying

PDF Search Title:

Comparing Vacuum Drying and Conventional DryingOriginal File Name Searched:

fpl_rp708.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |