PDF Publication Title:

Text from PDF Page: 004

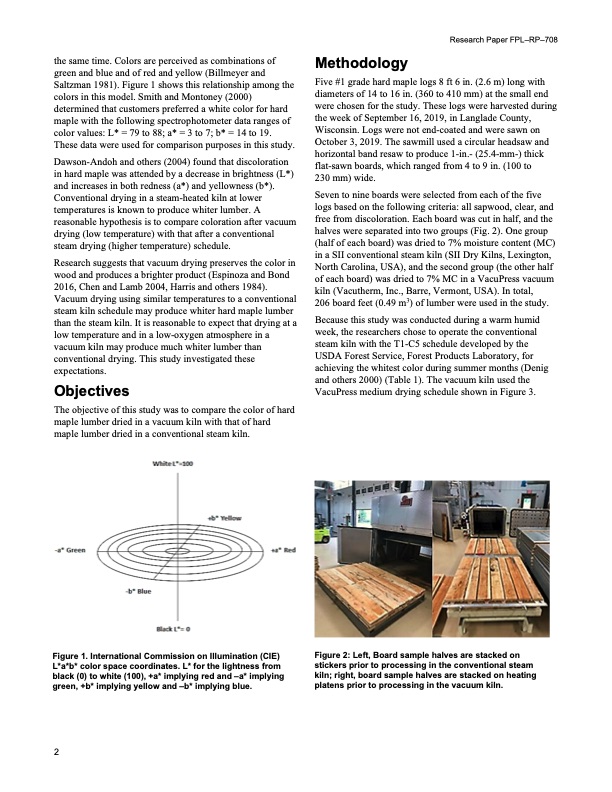

the same time. Colors are perceived as combinations of green and blue and of red and yellow (Billmeyer and Saltzman 1981). Figure 1 shows this relationship among the colors in this model. Smith and Montoney (2000) determined that customers preferred a white color for hard maple with the following spectrophotometer data ranges of color values: L* = 79 to 88; a* = 3 to 7; b* = 14 to 19. These data were used for comparison purposes in this study. Dawson-Andoh and others (2004) found that discoloration in hard maple was attended by a decrease in brightness (L*) and increases in both redness (a*) and yellowness (b*). Conventional drying in a steam-heated kiln at lower temperatures is known to produce whiter lumber. A reasonable hypothesis is to compare coloration after vacuum drying (low temperature) with that after a conventional steam drying (higher temperature) schedule. Research suggests that vacuum drying preserves the color in wood and produces a brighter product (Espinoza and Bond 2016, Chen and Lamb 2004, Harris and others 1984). Vacuum drying using similar temperatures to a conventional steam kiln schedule may produce whiter hard maple lumber than the steam kiln. It is reasonable to expect that drying at a low temperature and in a low-oxygen atmosphere in a vacuum kiln may produce much whiter lumber than conventional drying. This study investigated these expectations. Objectives The objective of this study was to compare the color of hard maple lumber dried in a vacuum kiln with that of hard maple lumber dried in a conventional steam kiln. Methodology Five #1 grade hard maple logs 8 ft 6 in. (2.6 m) long with diameters of 14 to 16 in. (360 to 410 mm) at the small end were chosen for the study. These logs were harvested during the week of September 16, 2019, in Langlade County, Wisconsin. Logs were not end-coated and were sawn on October 3, 2019. The sawmill used a circular headsaw and horizontal band resaw to produce 1-in.- (25.4-mm-) thick flat-sawn boards, which ranged from 4 to 9 in. (100 to 230 mm) wide. Seven to nine boards were selected from each of the five logs based on the following criteria: all sapwood, clear, and free from discoloration. Each board was cut in half, and the halves were separated into two groups (Fig. 2). One group (half of each board) was dried to 7% moisture content (MC) in a SII conventional steam kiln (SII Dry Kilns, Lexington, North Carolina, USA), and the second group (the other half of each board) was dried to 7% MC in a VacuPress vacuum kiln (Vacutherm, Inc., Barre, Vermont, USA). In total, 206 board feet (0.49 m3) of lumber were used in the study. Because this study was conducted during a warm humid week, the researchers chose to operate the conventional steam kiln with the T1-C5 schedule developed by the USDA Forest Service, Forest Products Laboratory, for achieving the whitest color during summer months (Denig and others 2000) (Table 1). The vacuum kiln used the VacuPress medium drying schedule shown in Figure 3. Research Paper FPL–RP–708 Figure 1. International Commission on Illumination (CIE) L*a*b* color space coordinates. L* for the lightness from black (0) to white (100), +a* implying red and –a* implying green, +b* implying yellow and –b* implying blue. Figure 2: Left, Board sample halves are stacked on stickers prior to processing in the conventional steam kiln; right, board sample halves are stacked on heating platens prior to processing in the vacuum kiln. 2PDF Image | Comparing Vacuum Drying and Conventional Drying

PDF Search Title:

Comparing Vacuum Drying and Conventional DryingOriginal File Name Searched:

fpl_rp708.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |