PDF Publication Title:

Text from PDF Page: 003

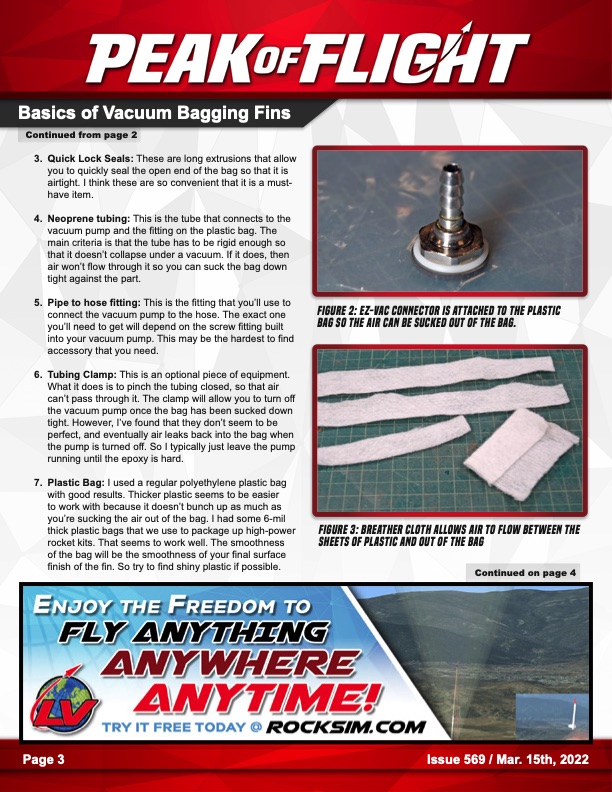

Basics of Vacuum Bagging Fins Continued from page 2 Continued on page 4 3. Quick Lock Seals: These are long extrusions that allow you to quickly seal the open end of the bag so that it is airtight. I think these are so convenient that it is a must- have item. 4. Neoprene tubing: This is the tube that connects to the vacuum pump and the fitting on the plastic bag. The main criteria is that the tube has to be rigid enough so that it doesn’t collapse under a vacuum. If it does, then air won’t flow through it so you can suck the bag down tight against the part. 5. Pipe to hose fitting: This is the fitting that you’ll use to connect the vacuum pump to the hose. The exact one you’ll need to get will depend on the screw fitting built into your vacuum pump. This may be the hardest to find accessory that you need. 6. Tubing Clamp: This is an optional piece of equipment. What it does is to pinch the tubing closed, so that air can’t pass through it. The clamp will allow you to turn off the vacuum pump once the bag has been sucked down tight. However, I’ve found that they don’t seem to be perfect, and eventually air leaks back into the bag when the pump is turned off. So I typically just leave the pump running until the epoxy is hard. 7. Plastic Bag: I used a regular polyethylene plastic bag with good results. Thicker plastic seems to be easier to work with because it doesn’t bunch up as much as you’re sucking the air out of the bag. I had some 6-mil thick plastic bags that we use to package up high-power rocket kits. That seems to work well. The smoothness of the bag will be the smoothness of your final surface finish of the fin. So try to find shiny plastic if possible. Figure 2: EZ-Vac connector is attached to the plastic bag so the air can be sucked out of the bag. Page 3 Issue 569 / Mar. 15th, 2022 Figure 3: Breather cloth allows air to flow between the sheets of plastic and out of the bagPDF Image | Basics of Vacuum Bagging Fins

PDF Search Title:

Basics of Vacuum Bagging FinsOriginal File Name Searched:

Newsletter569.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |