PDF Publication Title:

Text from PDF Page: 352

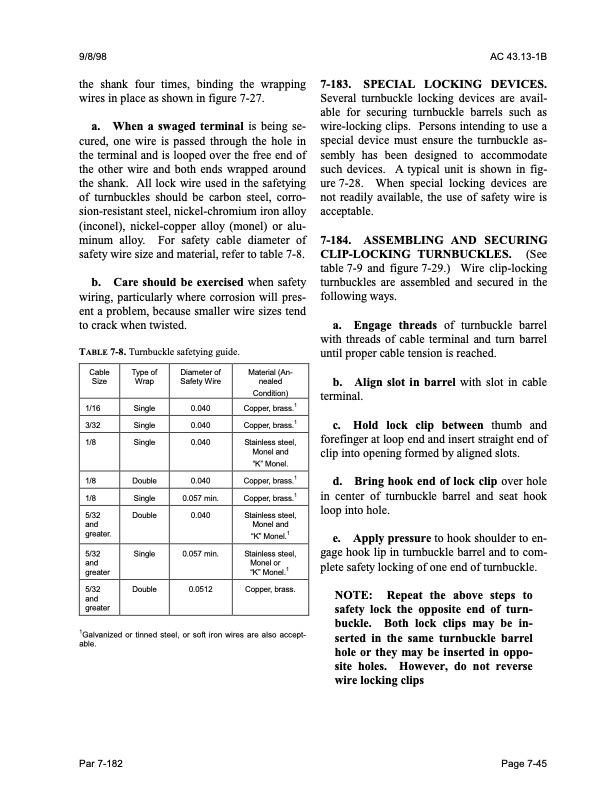

9/8/98 AC 43.13-1B the shank four times, binding the wrapping wires in place as shown in figure 7-27. a. When a swaged terminal is being se- cured, one wire is passed through the hole in the terminal and is looped over the free end of the other wire and both ends wrapped around the shank. All lock wire used in the safetying of turnbuckles should be carbon steel, corro- sion-resistant steel, nickel-chromium iron alloy (inconel), nickel-copper alloy (monel) or alu- minum alloy. For safety cable diameter of safety wire size and material, refer to table 7-8. b. Care should be exercised when safety wiring, particularly where corrosion will pres- ent a problem, because smaller wire sizes tend to crack when twisted. 7-183. SPECIAL LOCKING DEVICES. Several turnbuckle locking devices are avail- able for securing turnbuckle barrels such as wire-locking clips. Persons intending to use a special device must ensure the turnbuckle as- sembly has been designed to accommodate such devices. A typical unit is shown in fig- ure 7-28. When special locking devices are not readily available, the use of safety wire is acceptable. 7-184. ASSEMBLING AND SECURING CLIP-LOCKING TURNBUCKLES. (See table 7-9 and figure 7-29.) Wire clip-locking turnbuckles are assembled and secured in the following ways. a. Engage threads of turnbuckle barrel with threads of cable terminal and turn barrel until proper cable tension is reached. b. Align slot in barrel with slot in cable terminal. c. Hold lock clip between thumb and forefinger at loop end and insert straight end of clip into opening formed by aligned slots. d. Bring hook end of lock clip over hole in center of turnbuckle barrel and seat hook loop into hole. e. Apply pressure to hook shoulder to en- gage hook lip in turnbuckle barrel and to com- plete safety locking of one end of turnbuckle. NOTE: Repeat the above steps to safety lock the opposite end of turn- buckle. Both lock clips may be in- serted in the same turnbuckle barrel hole or they may be inserted in oppo- site holes. However, do not reverse wire locking clips TABLE 7-8. Turnbuckle safetying guide. Cable Type of Size Wrap 1/16 Single 3/32 Single 1/8 Single 1/8 Double 1/8 Single 5/32 Double and greater. Diameter of Safety Wire 0.040 0.040 0.040 0.040 0.057 min. 0.040 0.057 min. 0.0512 Material (An- nealed Condition) Copper, brass.1 Copper, brass.1 Stainless steel, Monel and “K” Monel. Copper, brass.1 Copper, brass.1 Stainless steel, Monel and “K” Monel.1 Stainless steel, Monel or “K” Monel.1 Copper, brass. 5/32 and greater Single 5/32 Double and greater 1Galvanized or tinned able. steel, or soft iron wires are also accept- Par 7-182 Page 7-45PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |