PDF Publication Title:

Text from PDF Page: 343

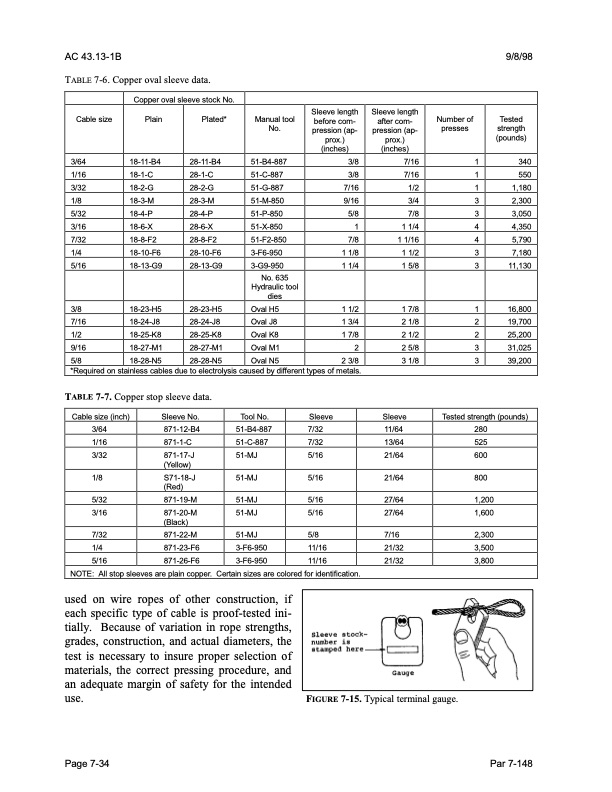

AC 43.13-1B 9/8/98 TABLE 7-6. Copper oval sleeve data. Copper oval sleeve stock No. Cable size Plain Plated* Manual tool No. Sleeve length before com- pression (ap- prox.) (inches) Sleeve length after com- pression (ap- prox.) (inches) Number of presses Tested strength (pounds) 3/64 18-11-B4 1/16 18-1-C 3/32 18-2-G 1/8 18-3-M 5/32 18-4-P 3/16 18-6-X 7/32 18-8-F2 1/4 18-10-F6 5/16 18-13-G9 3/8 18-23-H5 7/16 18-24-J8 1/2 18-25-K8 9/16 18-27-M1 5/8 18-28-N5 *Required on stainless cables due TABLE 7-7. Copper stop sleeve data. 28-11-B4 28-1-C 28-2-G 28-3-M 28-4-P 28-6-X 28-8-F2 28-10-F6 28-13-G9 28-23-H5 28-24-J8 28-25-K8 28-27-M1 51-B4-887 3/8 51-C-887 3/8 51-G-887 7/16 51-M-850 9/16 7/16 7/16 1/2 3/4 7/8 1 1/4 1 1/16 1 340 1 550 1 1,180 3 2,300 3 3,050 4 4,350 4 5,790 3 7,180 3 11,130 1 16,800 2 19,700 2 25,200 3 31,025 3 39,200 Tested strength (pounds) 280 525 600 800 1,200 1,600 2,300 3,500 3,800 51-P-850 51-X-850 51-F2-850 3-F6-950 3-G9-950 No. 635 Hydraulic tool dies Oval H5 Oval J8 Oval K8 Oval M1 Oval N5 5/8 1 7/8 1 1/8 1 1/4 1 1/2 1 3/4 1 7/8 1 1 1 2 2 2 3 Sleeve 11/64 13/64 21/64 21/64 27/64 27/64 7/16 21/32 21/32 1/2 5/8 7/8 1/8 1/2 5/8 1/8 2 2 3/8 28-28-N5 to electrolysis caused by different types of metals. Cable size 3/64 1/16 3/32 1/8 5/32 3/16 7/32 1/4 5/16 NOTE: All (inch) Sleeve No. 871-12-B4 871-1-C 871-17-J (Yellow) S71-18-J (Red) 871-19-M 871-20-M (Black) 871-22-M 871-23-F6 871-26-F6 Tool No. 51-B4-887 51-C-887 51-MJ 51-MJ 51-MJ 51-MJ 51-MJ 3-F6-950 3-F6-950 Sleeve 7/32 7/32 5/16 5/16 5/16 5/16 5/8 11/16 11/16 stop sleeves are plain copper. Certain sizes are colored for identification. used on wire ropes of other construction, if each specific type of cable is proof-tested ini tially. Because of variation in rope strengths, grades, construction, and actual diameters, the test is necessary to insure proper selection of materials, the correct pressing procedure, and an adequate margin of safety for the intended use. FIGURE 7-15. Typical terminal gauge. Page 7-34 Par 7-148PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |