PDF Publication Title:

Text from PDF Page: 292

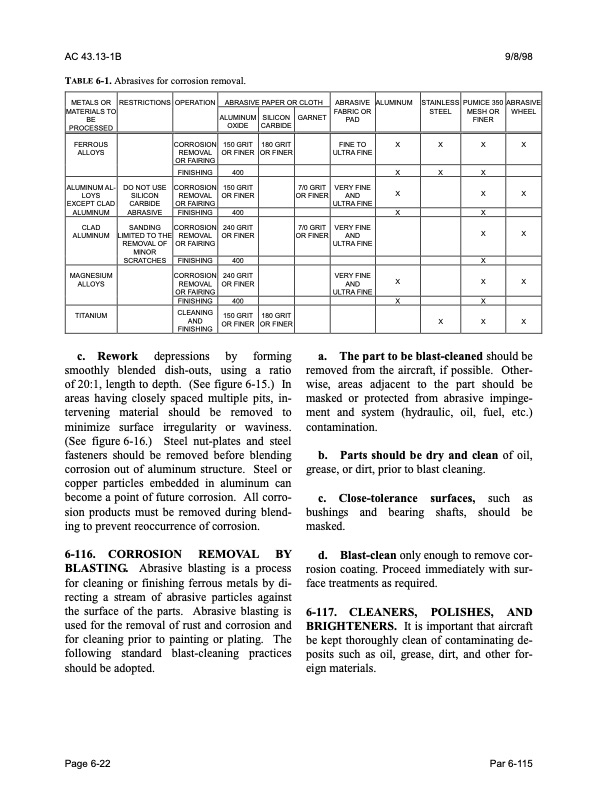

AC 43.13-1B 9/8/98 TABLE 6-1. Abrasives for corrosion removal. METALS OR RESTRICTIONS OPERATION ABRASIVE PAPER OR CLOTH ABRASIVE ALUMINUM STAINLESS PUMICE 350 ABRASIVE MATERIALS TO BE PROCESSED FERROUS CORROSION ALUMINUM SILICON GARNET FABRIC OR PAD STEEL MESH OR WHEEL FINER ALLOYS ALUMINUM AL- LOYS EXCEPT CLAD ALUMINUM REMOVAL OR FAIRING FINISHING CORROSION REMOVAL OR FAIRING FINISHING OXIDE 150 GRIT OR FINER 400 150 GRIT OR FINER 400 240 GRIT OR FINER 400 240 GRIT OR FINER 400 150 GRIT OR FINER CARBIDE 180 GRIT OR FINER FINE TO XXXX ULTRA FINE XXX XXX XX XX X XXX XX XXX DO NOT USE SILICON CARBIDE ABRASIVE VERY FINE AND ULTRA FINE VERY FINE AND ULTRA FINE VERY FINE AND ULTRA FINE 7/0 GRIT OR FINER 7/0 GRIT OR FINER a. b. Parts should be dry and clean of oil, grease, or dirt, prior to blast cleaning. c. Close-tolerance surfaces, such as bushings and bearing shafts, should be masked. d. Blast-clean only enough to remove cor rosion coating. Proceed immediately with sur face treatments as required. 6-117. CLEANERS, POLISHES, AND BRIGHTENERS. It is important that aircraft be kept thoroughly clean of contaminating de posits such as oil, grease, dirt, and other for eign materials. CLAD SANDING CORROSION ALUMINUM LIMITED TO THE REMOVAL OF REMOVAL OR FAIRING MINOR SCRATCHES FINISHING MAGNESIUM CORROSION ALLOYS TITANIUM REMOVAL OR FAIRING FINISHING CLEANING AND FINISHING 180 GRIT OR FINER c. Rework depressions by forming smoothly blended dish-outs, using a ratio of 20:1, length to depth. (See figure 6-15.) In areas having closely spaced multiple pits, in tervening material should be removed to minimize surface irregularity or waviness. (See figure 6-16.) Steel nut-plates and steel fasteners should be removed before blending corrosion out of aluminum structure. Steel or copper particles embedded in aluminum can become a point of future corrosion. All corro sion products must be removed during blend ing to prevent reoccurrence of corrosion. 6-116. CORROSION REMOVAL BY BLASTING. Abrasive blasting is a process for cleaning or finishing ferrous metals by di recting a stream of abrasive particles against the surface of the parts. Abrasive blasting is used for the removal of rust and corrosion and for cleaning prior to painting or plating. The following standard blast-cleaning practices should be adopted. The part to be blast-cleaned should be removed from the aircraft, if possible. Other wise, areas adjacent to the part should be masked or protected from abrasive impinge ment and system (hydraulic, oil, fuel, etc.) contamination. Page 6-22 Par 6-115PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |