PDF Publication Title:

Text from PDF Page: 280

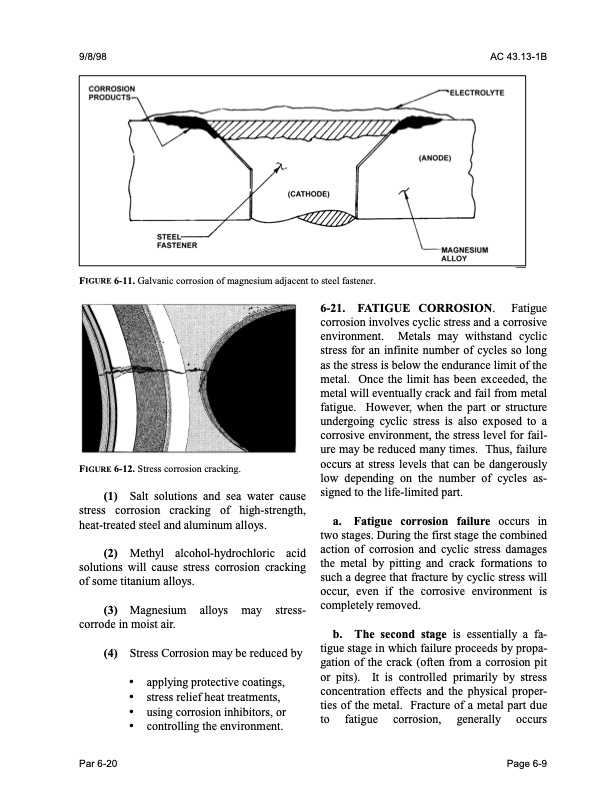

9/8/98 AC 43.13-1B FIGURE 6-11. Galvanic corrosion of magnesium adjacent to steel fastener. FIGURE 6-12. Stress corrosion cracking. (1) Salt solutions and sea water cause stress corrosion cracking of high-strength, heat-treated steel and aluminum alloys. (2) Methyl alcohol-hydrochloric acid solutions will cause stress corrosion cracking of some titanium alloys. (3) Magnesium alloys may stress- corrode in moist air. 6-21. FATIGUE CORROSION. Fatigue corrosion involves cyclic stress and a corrosive environment. Metals may withstand cyclic stress for an infinite number of cycles so long as the stress is below the endurance limit of the metal. Once the limit has been exceeded, the metal will eventually crack and fail from metal fatigue. However, when the part or structure undergoing cyclic stress is also exposed to a corrosive environment, the stress level for fail ure may be reduced many times. Thus, failure occurs at stress levels that can be dangerously low depending on the number of cycles as signed to the life-limited part. a. Fatigue corrosion failure occurs in two stages. During the first stage the combined action of corrosion and cyclic stress damages the metal by pitting and crack formations to such a degree that fracture by cyclic stress will occur, even if the corrosive environment is completely removed. b. The second stage is essentially a fa tigue stage in which failure proceeds by propa gation of the crack (often from a corrosion pit or pits). It is controlled primarily by stress concentration effects and the physical proper ties of the metal. Fracture of a metal part due Par 6-20 Page 6-9 (4) Stress Corrosion may be reduced by • applying protective coatings, • stress relief heat treatments, • using corrosion inhibitors, or • controlling the environment. to fatigue corrosion, generally occursPDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |