PDF Publication Title:

Text from PDF Page: 278

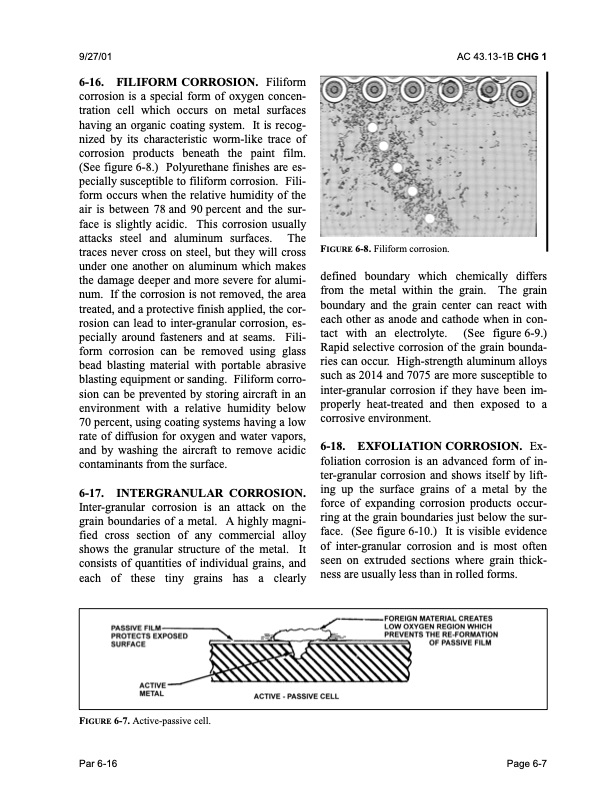

9/27/01 AC 43.13-1B CHG 1 6-16. FILIFORM CORROSION. Filiform corrosion is a special form of oxygen concen tration cell which occurs on metal surfaces having an organic coating system. It is recog nized by its characteristic worm-like trace of corrosion products beneath the paint film. (See figure 6-8.) Polyurethane finishes are es pecially susceptible to filiform corrosion. Fili form occurs when the relative humidity of the air is between 78 and 90 percent and the sur face is slightly acidic. This corrosion usually attacks steel and aluminum surfaces. The traces never cross on steel, but they will cross under one another on aluminum which makes the damage deeper and more severe for alumi num. If the corrosion is not removed, the area treated, and a protective finish applied, the cor rosion can lead to inter-granular corrosion, es pecially around fasteners and at seams. Fili form corrosion can be removed using glass bead blasting material with portable abrasive blasting equipment or sanding. Filiform corro sion can be prevented by storing aircraft in an environment with a relative humidity below 70 percent, using coating systems having a low rate of diffusion for oxygen and water vapors, and by washing the aircraft to remove acidic contaminants from the surface. 6-17. INTERGRANULAR CORROSION. Inter-granular corrosion is an attack on the grain boundaries of a metal. A highly magni fied cross section of any commercial alloy shows the granular structure of the metal. It consists of quantities of individual grains, and each of these tiny grains has a clearly FIGURE 6-8. Filiform corrosion. defined boundary which chemically differs from the metal within the grain. The grain boundary and the grain center can react with each other as anode and cathode when in con tact with an electrolyte. (See figure 6-9.) Rapid selective corrosion of the grain bounda ries can occur. High-strength aluminum alloys such as 2014 and 7075 are more susceptible to inter-granular corrosion if they have been im properly heat-treated and then exposed to a corrosive environment. 6-18. EXFOLIATION CORROSION. Ex- foliation corrosion is an advanced form of in ter-granular corrosion and shows itself by lift ing up the surface grains of a metal by the force of expanding corrosion products occur ring at the grain boundaries just below the sur face. (See figure 6-10.) It is visible evidence of inter-granular corrosion and is most often seen on extruded sections where grain thick ness are usually less than in rolled forms. FIGURE 6-7. Active-passive cell. Par 6-16 Page 6-7PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |