PDF Publication Title:

Text from PDF Page: 251

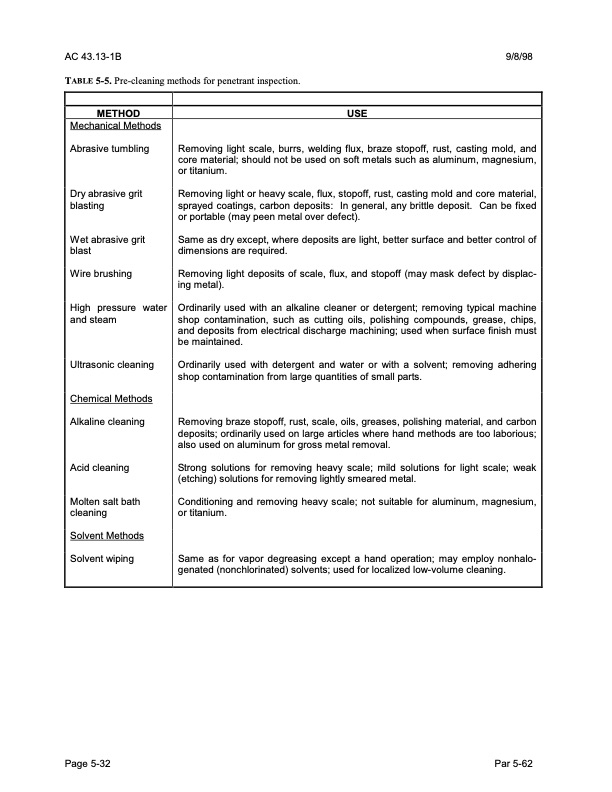

AC 43.13-1B 9/8/98 TABLE 5-5. Pre-cleaning methods for penetrant inspection. METHOD USE Mechanical Methods Abrasive tumbling Dry abrasive grit blasting Wet abrasive grit blast Wire brushing High pressure water and steam Ultrasonic cleaning Chemical Methods Alkaline cleaning Acid cleaning Molten salt bath cleaning Solvent Methods Solvent wiping Removing light scale, burrs, welding flux, braze stopoff, rust, casting mold, and core material; should not be used on soft metals such as aluminum, magnesium, or titanium. Removing light or heavy scale, flux, stopoff, rust, casting mold and core material, sprayed coatings, carbon deposits: In general, any brittle deposit. Can be fixed or portable (may peen metal over defect). Same as dry except, where deposits are light, better surface and better control of dimensions are required. Removing light deposits of scale, flux, and stopoff (may mask defect by displac- ing metal). Ordinarily used with an alkaline cleaner or detergent; removing typical machine shop contamination, such as cutting oils, polishing compounds, grease, chips, and deposits from electrical discharge machining; used when surface finish must be maintained. Ordinarily used with detergent and water or with a solvent; removing adhering shop contamination from large quantities of small parts. Removing braze stopoff, rust, scale, oils, greases, polishing material, and carbon deposits; ordinarily used on large articles where hand methods are too laborious; also used on aluminum for gross metal removal. Strong solutions for removing heavy scale; mild solutions for light scale; weak (etching) solutions for removing lightly smeared metal. Conditioning and removing heavy scale; not suitable for aluminum, magnesium, or titanium. Same as for vapor degreasing except a hand operation; may employ nonhalo- genated (nonchlorinated) solvents; used for localized low-volume cleaning. Page 5-32 Par 5-62PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |