PDF Publication Title:

Text from PDF Page: 242

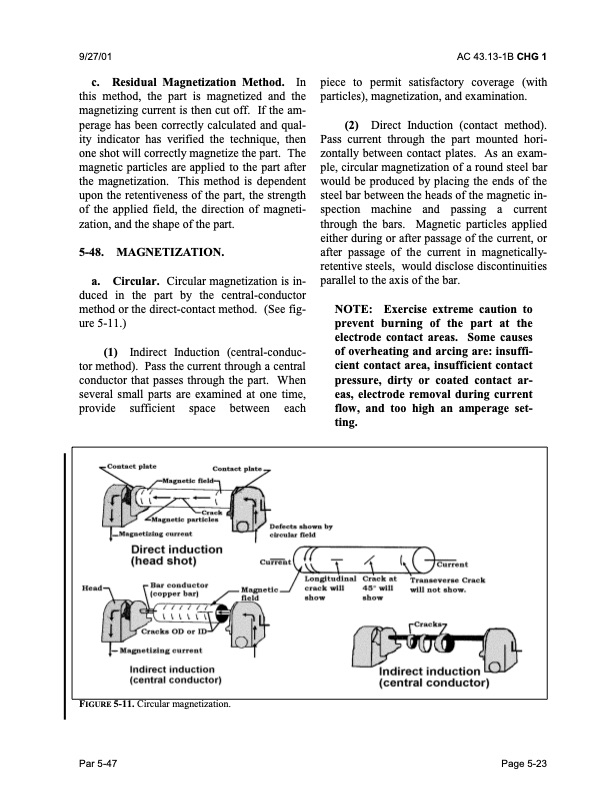

9/27/01 c. Residual Magnetization Method. In this method, the part is magnetized and the magnetizing current is then cut off. If the am- perage has been correctly calculated and qual- ity indicator has verified the technique, then one shot will correctly magnetize the part. The magnetic particles are applied to the part after the magnetization. This method is dependent upon the retentiveness of the part, the strength of the applied field, the direction of magneti- zation, and the shape of the part. 5-48. MAGNETIZATION. a. Circular. Circular magnetization is in- duced in the part by the central-conductor method or the direct-contact method. (See fig- ure 5-11.) (1) Indirect Induction (central-conduc- tor method). Pass the current through a central conductor that passes through the part. When several small parts are examined at one time, provide sufficient space between each AC 43.13-1B CHG 1 piece to permit satisfactory coverage (with particles), magnetization, and examination. (2) Direct Induction (contact method). Pass current through the part mounted hori- zontally between contact plates. As an exam- ple, circular magnetization of a round steel bar would be produced by placing the ends of the steel bar between the heads of the magnetic in- spection machine and passing a current through the bars. Magnetic particles applied either during or after passage of the current, or after passage of the current in magnetically- retentive steels, would disclose discontinuities parallel to the axis of the bar. NOTE: Exercise extreme caution to prevent burning of the part at the electrode contact areas. Some causes of overheating and arcing are: insuffi- cient contact area, insufficient contact pressure, dirty or coated contact ar- eas, electrode removal during current flow, and too high an amperage set- ting. FIGURE 5-11. Circular magnetization. Par 5-47 Page 5-23PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |