PDF Publication Title:

Text from PDF Page: 238

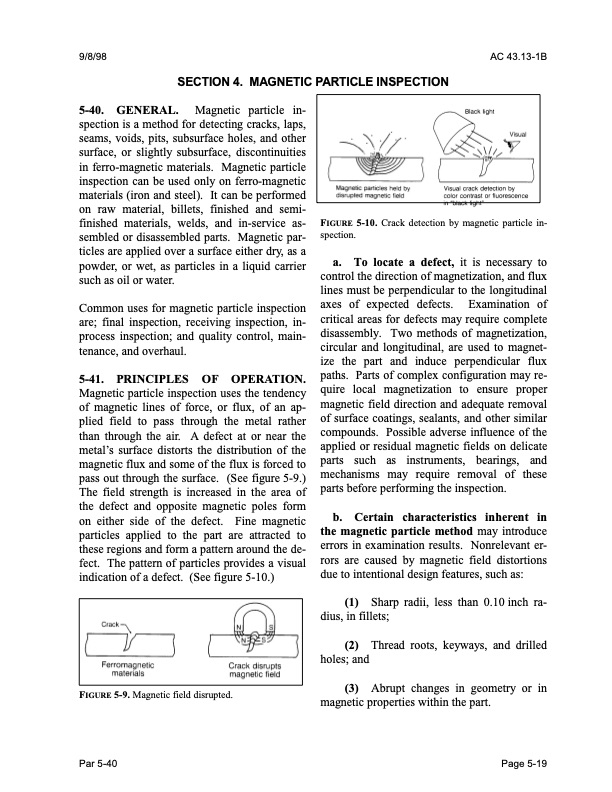

9/8/98 AC 43.13-1B SECTION 4. MAGNETIC PARTICLE INSPECTION 5-40. GENERAL. Magnetic particle in- spection is a method for detecting cracks, laps, seams, voids, pits, subsurface holes, and other surface, or slightly subsurface, discontinuities in ferro-magnetic materials. Magnetic particle inspection can be used only on ferro-magnetic materials (iron and steel). It can be performed on raw material, billets, finished and semi- finished materials, welds, and in-service as- sembled or disassembled parts. Magnetic par- ticles are applied over a surface either dry, as a powder, or wet, as particles in a liquid carrier such as oil or water. Common uses for magnetic particle inspection are; final inspection, receiving inspection, in- process inspection; and quality control, main- tenance, and overhaul. 5-41. PRINCIPLES OF OPERATION. Magnetic particle inspection uses the tendency of magnetic lines of force, or flux, of an ap- plied field to pass through the metal rather than through the air. A defect at or near the metal’s surface distorts the distribution of the magnetic flux and some of the flux is forced to pass out through the surface. (See figure 5-9.) The field strength is increased in the area of the defect and opposite magnetic poles form on either side of the defect. Fine magnetic particles applied to the part are attracted to these regions and form a pattern around the de- fect. The pattern of particles provides a visual indication of a defect. (See figure 5-10.) FIGURE 5-9. Magnetic field disrupted. FIGURE 5-10. Crack detection by magnetic particle in- spection. a. To locate a defect, it is necessary to control the direction of magnetization, and flux lines must be perpendicular to the longitudinal axes of expected defects. Examination of critical areas for defects may require complete disassembly. Two methods of magnetization, circular and longitudinal, are used to magnet- ize the part and induce perpendicular flux paths. Parts of complex configuration may re- quire local magnetization to ensure proper magnetic field direction and adequate removal of surface coatings, sealants, and other similar compounds. Possible adverse influence of the applied or residual magnetic fields on delicate parts such as instruments, bearings, and mechanisms may require removal of these parts before performing the inspection. b. Certain characteristics inherent in the magnetic particle method may introduce errors in examination results. Nonrelevant er- rors are caused by magnetic field distortions due to intentional design features, such as: (1) Sharp radii, less than 0.10 inch ra- dius, in fillets; (2) Thread roots, keyways, and drilled holes; and (3) Abrupt changes in geometry or in magnetic properties within the part. Par 5-40 Page 5-19PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |