PDF Publication Title:

Text from PDF Page: 235

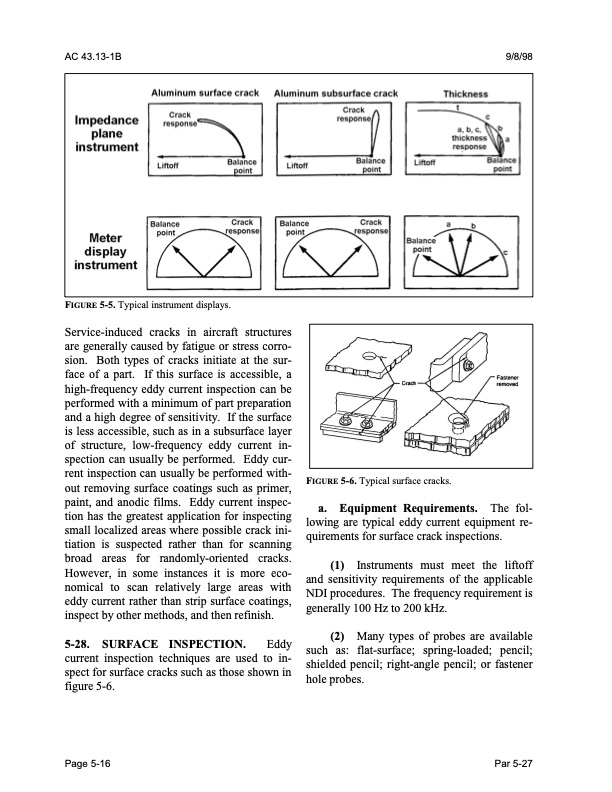

AC 43.13-1B 9/8/98 FIGURE 5-5. Typical instrument displays. Service-induced cracks in aircraft structures are generally caused by fatigue or stress corro- sion. Both types of cracks initiate at the sur- face of a part. If this surface is accessible, a high-frequency eddy current inspection can be performed with a minimum of part preparation and a high degree of sensitivity. If the surface is less accessible, such as in a subsurface layer of structure, low-frequency eddy current in- spection can usually be performed. Eddy cur- rent inspection can usually be performed with- out removing surface coatings such as primer, paint, and anodic films. Eddy current inspec- tion has the greatest application for inspecting small localized areas where possible crack ini- tiation is suspected rather than for scanning broad areas for randomly-oriented cracks. However, in some instances it is more eco- nomical to scan relatively large areas with eddy current rather than strip surface coatings, inspect by other methods, and then refinish. 5-28. SURFACE INSPECTION. Eddy current inspection techniques are used to in- spect for surface cracks such as those shown in figure 5-6. FIGURE 5-6. Typical surface cracks. a. Equipment Requirements. The fol- lowing are typical eddy current equipment re- quirements for surface crack inspections. (1) Instruments must meet the liftoff and sensitivity requirements of the applicable NDI procedures. The frequency requirement is generally 100 Hz to 200 kHz. (2) Many types of probes are available such as: flat-surface; spring-loaded; pencil; shielded pencil; right-angle pencil; or fastener hole probes. Page 5-16 Par 5-27PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |