PDF Publication Title:

Text from PDF Page: 200

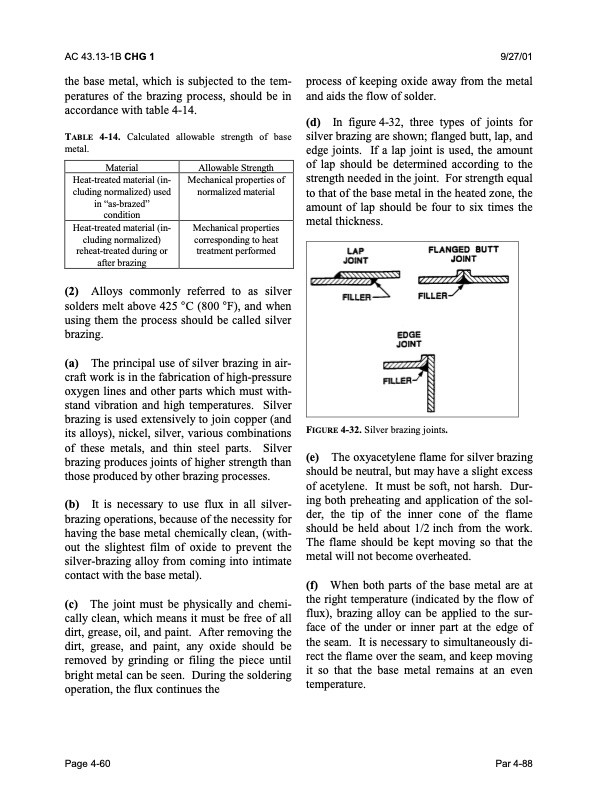

AC 43.13-1B CHG 1 9/27/01 the base metal, which is subjected to the tem peratures of the brazing process, should be in accordance with table 4-14. TABLE 4-14. Calculated allowable strength of base metal. process of keeping oxide away from the metal and aids the flow of solder. (d) In figure 4-32, three types of joints for silver brazing are shown; flanged butt, lap, and edge joints. If a lap joint is used, the amount of lap should be determined according to the strength needed in the joint. For strength equal to that of the base metal in the heated zone, the amount of lap should be four to six times the metal thickness. FIGURE 4-32. Silver brazing joints. (e) The oxyacetylene flame for silver brazing should be neutral, but may have a slight excess of acetylene. It must be soft, not harsh. Dur ing both preheating and application of the sol der, the tip of the inner cone of the flame should be held about 1/2 inch from the work. The flame should be kept moving so that the metal will not become overheated. (f) When both parts of the base metal are at the right temperature (indicated by the flow of flux), brazing alloy can be applied to the sur face of the under or inner part at the edge of the seam. It is necessary to simultaneously di rect the flame over the seam, and keep moving it so that the base metal remains at an even temperature. Material Allowable Strength Heat-treated material (in cluding normalized) used in “as-brazed” condition Mechanical properties of normalized material Heat-treated material (in cluding normalized) reheat-treated during or after brazing Mechanical properties corresponding to heat treatment performed (2) Alloys commonly referred to as silver solders melt above 425 °C (800 °F), and when using them the process should be called silver brazing. (a) The principal use of silver brazing in air craft work is in the fabrication of high-pressure oxygen lines and other parts which must with stand vibration and high temperatures. Silver brazing is used extensively to join copper (and its alloys), nickel, silver, various combinations of these metals, and thin steel parts. Silver brazing produces joints of higher strength than those produced by other brazing processes. (b) It is necessary to use flux in all silver- brazing operations, because of the necessity for having the base metal chemically clean, (with out the slightest film of oxide to prevent the silver-brazing alloy from coming into intimate contact with the base metal). (c) The joint must be physically and chemi cally clean, which means it must be free of all dirt, grease, oil, and paint. After removing the dirt, grease, and paint, any oxide should be removed by grinding or filing the piece until bright metal can be seen. During the soldering operation, the flux continues the Page 4-60 Par 4-88PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |