PDF Publication Title:

Text from PDF Page: 139

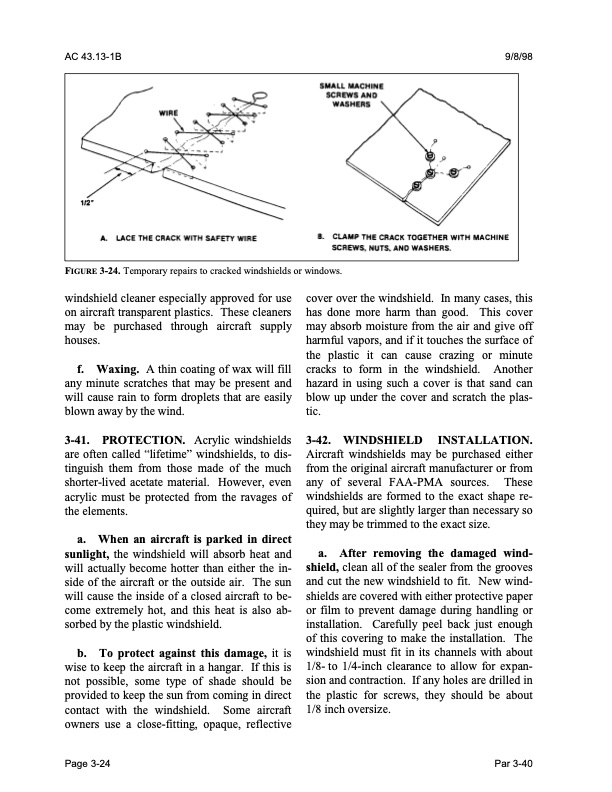

AC 43.13-1B 9/8/98 FIGURE 3-24. Temporary repairs to cracked windshields or windows. windshield cleaner especially approved for use on aircraft transparent plastics. These cleaners may be purchased through aircraft supply houses. f. Waxing. A thin coating of wax will fill any minute scratches that may be present and will cause rain to form droplets that are easily blown away by the wind. 3-41. PROTECTION. Acrylic windshields are often called “lifetime” windshields, to dis tinguish them from those made of the much shorter-lived acetate material. However, even acrylic must be protected from the ravages of the elements. a. When an aircraft is parked in direct sunlight, the windshield will absorb heat and will actually become hotter than either the in side of the aircraft or the outside air. The sun will cause the inside of a closed aircraft to be come extremely hot, and this heat is also ab sorbed by the plastic windshield. b. To protect against this damage, it is wise to keep the aircraft in a hangar. If this is not possible, some type of shade should be provided to keep the sun from coming in direct contact with the windshield. Some aircraft owners use a close-fitting, opaque, reflective cover over the windshield. In many cases, this has done more harm than good. This cover may absorb moisture from the air and give off harmful vapors, and if it touches the surface of the plastic it can cause crazing or minute cracks to form in the windshield. Another hazard in using such a cover is that sand can blow up under the cover and scratch the plas tic. 3-42. WINDSHIELD INSTALLATION. Aircraft windshields may be purchased either from the original aircraft manufacturer or from any of several FAA-PMA sources. These windshields are formed to the exact shape re quired, but are slightly larger than necessary so they may be trimmed to the exact size. a. After removing the damaged wind- shield, clean all of the sealer from the grooves and cut the new windshield to fit. New wind shields are covered with either protective paper or film to prevent damage during handling or installation. Carefully peel back just enough of this covering to make the installation. The windshield must fit in its channels with about 1/8- to 1/4-inch clearance to allow for expan sion and contraction. If any holes are drilled in the plastic for screws, they should be about 1/8 inch oversize. Page 3-24 Par 3-40PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |