PDF Publication Title:

Text from PDF Page: 127

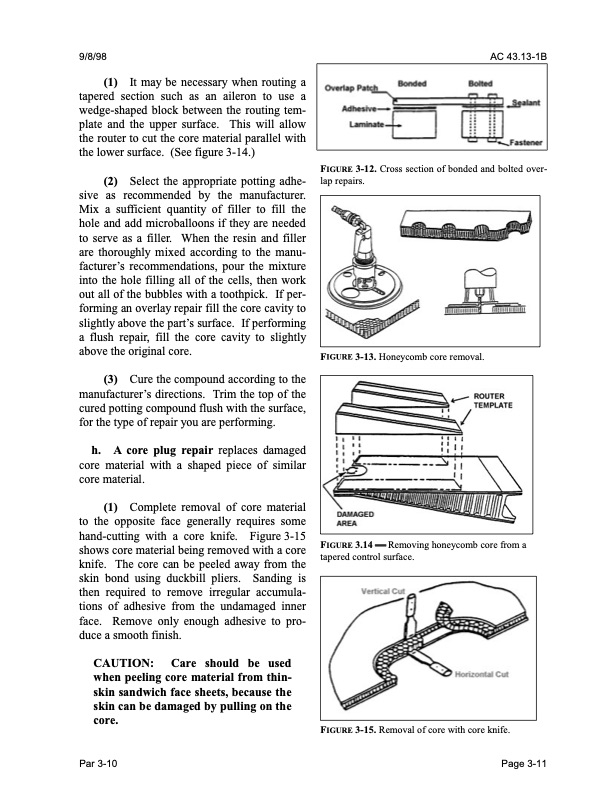

9/8/98 AC 43.13-1B (1) It may be necessary when routing a tapered section such as an aileron to use a wedge-shaped block between the routing tem plate and the upper surface. This will allow the router to cut the core material parallel with the lower surface. (See figure 3-14.) (2) Select the appropriate potting adhe sive as recommended by the manufacturer. Mix a sufficient quantity of filler to fill the hole and add microballoons if they are needed to serve as a filler. When the resin and filler are thoroughly mixed according to the manu facturer’s recommendations, pour the mixture into the hole filling all of the cells, then work out all of the bubbles with a toothpick. If per forming an overlay repair fill the core cavity to slightly above the part’s surface. If performing a flush repair, fill the core cavity to slightly above the original core. (3) Cure the compound according to the manufacturer’s directions. Trim the top of the cured potting compound flush with the surface, for the type of repair you are performing. h. A core plug repair replaces damaged core material with a shaped piece of similar core material. (1) Complete removal of core material to the opposite face generally requires some hand-cutting with a core knife. Figure 3-15 shows core material being removed with a core knife. The core can be peeled away from the skin bond using duckbill pliers. Sanding is then required to remove irregular accumula tions of adhesive from the undamaged inner face. Remove only enough adhesive to pro duce a smooth finish. CAUTION: Care should be used when peeling core material from thin- skin sandwich face sheets, because the skin can be damaged by pulling on the core. Par 3-10 FIGURE 3-12. Cross section of bonded and bolted over lap repairs. FIGURE 3-13. Honeycomb core removal. FIGURE 3.14 Removing honeycomb core from a tapered control surface. FIGURE 3-15. Removal of core with core knife. Page 3-11PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |