PDF Publication Title:

Text from PDF Page: 114

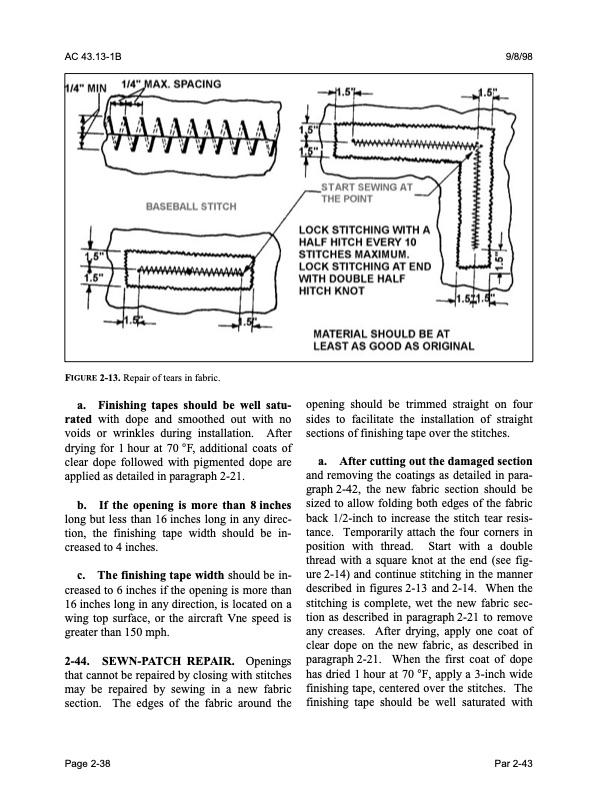

AC 43.13-1B 9/8/98 FIGURE 2-13. Repair of tears in fabric. a. Finishing tapes should be well satu- rated with dope and smoothed out with no voids or wrinkles during installation. After drying for 1 hour at 70 °F, additional coats of clear dope followed with pigmented dope are applied as detailed in paragraph 2-21. b. If the opening is more than 8 inches long but less than 16 inches long in any direc tion, the finishing tape width should be in creased to 4 inches. c. The finishing tape width should be in creased to 6 inches if the opening is more than 16 inches long in any direction, is located on a wing top surface, or the aircraft Vne speed is greater than 150 mph. 2-44. SEWN-PATCH REPAIR. Openings that cannot be repaired by closing with stitches may be repaired by sewing in a new fabric section. The edges of the fabric around the opening should be trimmed straight on four sides to facilitate the installation of straight sections of finishing tape over the stitches. a. After cutting out the damaged section and removing the coatings as detailed in para graph 2-42, the new fabric section should be sized to allow folding both edges of the fabric back 1/2-inch to increase the stitch tear resis tance. Temporarily attach the four corners in position with thread. Start with a double thread with a square knot at the end (see fig ure 2-14) and continue stitching in the manner described in figures 2-13 and 2-14. When the stitching is complete, wet the new fabric sec tion as described in paragraph 2-21 to remove any creases. After drying, apply one coat of clear dope on the new fabric, as described in paragraph 2-21. When the first coat of dope has dried 1 hour at 70 °F, apply a 3-inch wide finishing tape, centered over the stitches. The finishing tape should be well saturated with Page 2-38 Par 2-43PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |