PDF Publication Title:

Text from PDF Page: 045

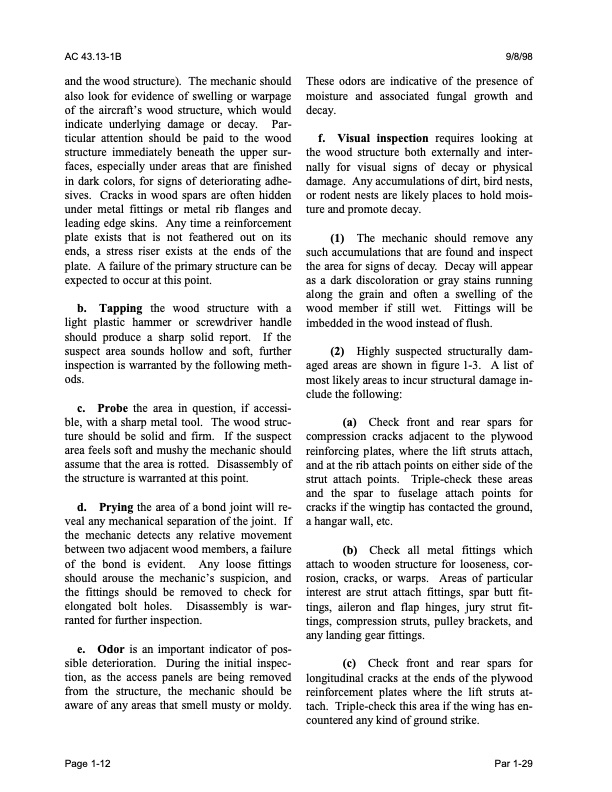

AC 43.13-1B 9/8/98 and the wood structure). The mechanic should also look for evidence of swelling or warpage of the aircraft’s wood structure, which would indicate underlying damage or decay. Par- ticular attention should be paid to the wood structure immediately beneath the upper sur- faces, especially under areas that are finished in dark colors, for signs of deteriorating adhe- sives. Cracks in wood spars are often hidden under metal fittings or metal rib flanges and leading edge skins. Any time a reinforcement plate exists that is not feathered out on its ends, a stress riser exists at the ends of the plate. A failure of the primary structure can be expected to occur at this point. b. Tapping the wood structure with a light plastic hammer or screwdriver handle should produce a sharp solid report. If the suspect area sounds hollow and soft, further inspection is warranted by the following meth- ods. c. Probe the area in question, if accessi- ble, with a sharp metal tool. The wood struc- ture should be solid and firm. If the suspect area feels soft and mushy the mechanic should assume that the area is rotted. Disassembly of the structure is warranted at this point. d. Prying the area of a bond joint will re- veal any mechanical separation of the joint. If the mechanic detects any relative movement between two adjacent wood members, a failure of the bond is evident. Any loose fittings should arouse the mechanic’s suspicion, and the fittings should be removed to check for elongated bolt holes. Disassembly is war- ranted for further inspection. e. Odor is an important indicator of pos- sible deterioration. During the initial inspec- tion, as the access panels are being removed from the structure, the mechanic should be aware of any areas that smell musty or moldy. These odors are indicative of the presence of moisture and associated fungal growth and decay. f. Visual inspection requires looking at the wood structure both externally and inter- nally for visual signs of decay or physical damage. Any accumulations of dirt, bird nests, or rodent nests are likely places to hold mois- ture and promote decay. (1) The mechanic should remove any such accumulations that are found and inspect the area for signs of decay. Decay will appear as a dark discoloration or gray stains running along the grain and often a swelling of the wood member if still wet. Fittings will be imbedded in the wood instead of flush. (2) Highly suspected structurally dam- aged areas are shown in figure 1-3. A list of most likely areas to incur structural damage in- clude the following: (a) Check front and rear spars for compression cracks adjacent to the plywood reinforcing plates, where the lift struts attach, and at the rib attach points on either side of the strut attach points. Triple-check these areas and the spar to fuselage attach points for cracks if the wingtip has contacted the ground, a hangar wall, etc. (b) Check all metal fittings which attach to wooden structure for looseness, cor- rosion, cracks, or warps. Areas of particular interest are strut attach fittings, spar butt fit- tings, aileron and flap hinges, jury strut fit- tings, compression struts, pulley brackets, and any landing gear fittings. (c) Check front and rear spars for longitudinal cracks at the ends of the plywood reinforcement plates where the lift struts at- tach. Triple-check this area if the wing has en- countered any kind of ground strike. Page 1-12 Par 1-29PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |