PDF Publication Title:

Text from PDF Page: 001

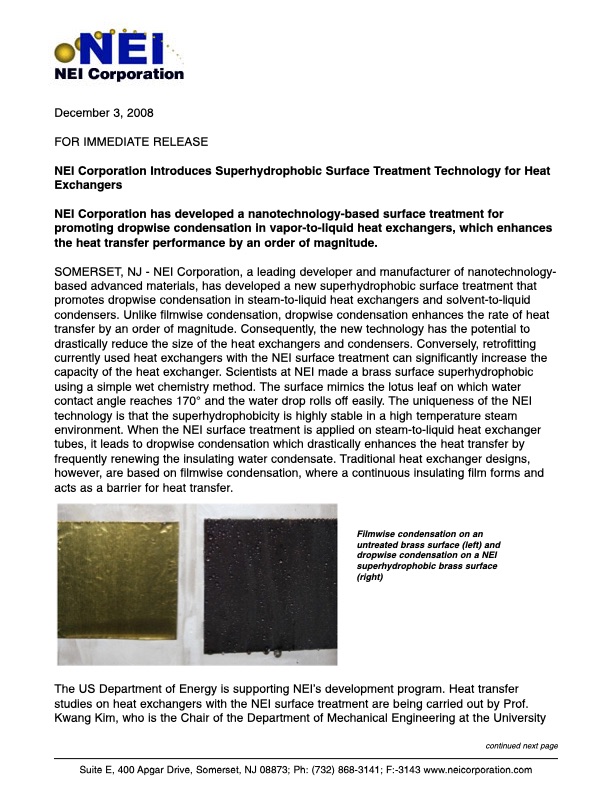

December 3, 2008 FOR IMMEDIATE RELEASE NEI Corporation Introduces Superhydrophobic Surface Treatment Technology for Heat Exchangers NEI Corporation has developed a nanotechnology-based surface treatment for promoting dropwise condensation in vapor-to-liquid heat exchangers, which enhances the heat transfer performance by an order of magnitude. SOMERSET, NJ - NEI Corporation, a leading developer and manufacturer of nanotechnology- based advanced materials, has developed a new superhydrophobic surface treatment that promotes dropwise condensation in steam-to-liquid heat exchangers and solvent-to-liquid condensers. Unlike filmwise condensation, dropwise condensation enhances the rate of heat transfer by an order of magnitude. Consequently, the new technology has the potential to drastically reduce the size of the heat exchangers and condensers. Conversely, retrofitting currently used heat exchangers with the NEI surface treatment can significantly increase the capacity of the heat exchanger. Scientists at NEI made a brass surface superhydrophobic using a simple wet chemistry method. The surface mimics the lotus leaf on which water contact angle reaches 170° and the water drop rolls off easily. The uniqueness of the NEI technology is that the superhydrophobicity is highly stable in a high temperature steam environment. When the NEI surface treatment is applied on steam-to-liquid heat exchanger tubes, it leads to dropwise condensation which drastically enhances the heat transfer by frequently renewing the insulating water condensate. Traditional heat exchanger designs, however, are based on filmwise condensation, where a continuous insulating film forms and acts as a barrier for heat transfer. Filmwise condensation on an untreated brass surface (left) and dropwise condensation on a NEI superhydrophobic brass surface (right) The US Department of Energy is supporting NEI’s development program. Heat transfer studies on heat exchangers with the NEI surface treatment are being carried out by Prof. Kwang Kim, who is the Chair of the Department of Mechanical Engineering at the University continued next page Suite E, 400 Apgar Drive, Somerset, NJ 08873; Ph: (732) 868-3141; F:-3143 www.neicorporation.comPDF Image | NEI Corporation Introduces Superhydrophobic Surface Treatment Technology for Heat Exchangers

PDF Search Title:

NEI Corporation Introduces Superhydrophobic Surface Treatment Technology for Heat ExchangersOriginal File Name Searched:

NEI_NanoFluids.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |