PDF Publication Title:

Text from PDF Page: 007

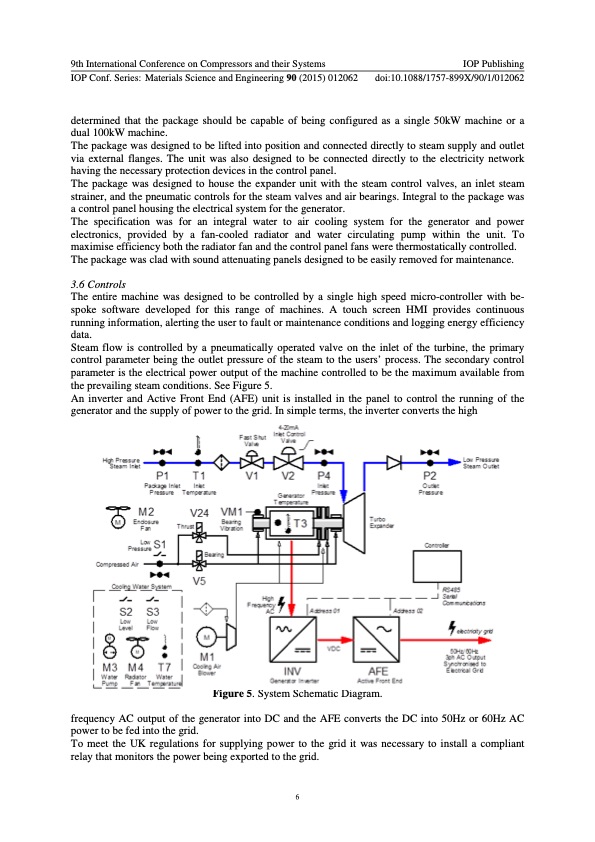

9th International Conference on Compressors and their Systems IOP Publishing IOP Conf. Series: Materials Science and Engineering 90 (2015) 012062 doi:10.1088/1757-899X/90/1/012062 determined that the package should be capable of being configured as a single 50kW machine or a dual 100kW machine. The package was designed to be lifted into position and connected directly to steam supply and outlet via external flanges. The unit was also designed to be connected directly to the electricity network having the necessary protection devices in the control panel. The package was designed to house the expander unit with the steam control valves, an inlet steam strainer, and the pneumatic controls for the steam valves and air bearings. Integral to the package was a control panel housing the electrical system for the generator. The specification was for an integral water to air cooling system for the generator and power electronics, provided by a fan-cooled radiator and water circulating pump within the unit. To maximise efficiency both the radiator fan and the control panel fans were thermostatically controlled. The package was clad with sound attenuating panels designed to be easily removed for maintenance. 3.6 Controls The entire machine was designed to be controlled by a single high speed micro-controller with be- spoke software developed for this range of machines. A touch screen HMI provides continuous running information, alerting the user to fault or maintenance conditions and logging energy efficiency data. Steam flow is controlled by a pneumatically operated valve on the inlet of the turbine, the primary control parameter being the outlet pressure of the steam to the users’ process. The secondary control parameter is the electrical power output of the machine controlled to be the maximum available from the prevailing steam conditions. See Figure 5. An inverter and Active Front End (AFE) unit is installed in the panel to control the running of the generator and the supply of power to the grid. In simple terms, the inverter converts the high Figure 5. System Schematic Diagram. frequency AC output of the generator into DC and the AFE converts the DC into 50Hz or 60Hz AC power to be fed into the grid. To meet the UK regulations for supplying power to the grid it was necessary to install a compliant relay that monitors the power being exported to the grid. 6PDF Image | IOP Science The Development of a Small High Speed Steam Microturbine Generator System

PDF Search Title:

IOP Science The Development of a Small High Speed Steam Microturbine Generator SystemOriginal File Name Searched:

1757-899X_90_1_012062.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |